Euro solar is Surfacing – pv magazine International

From pv journal 05/23.

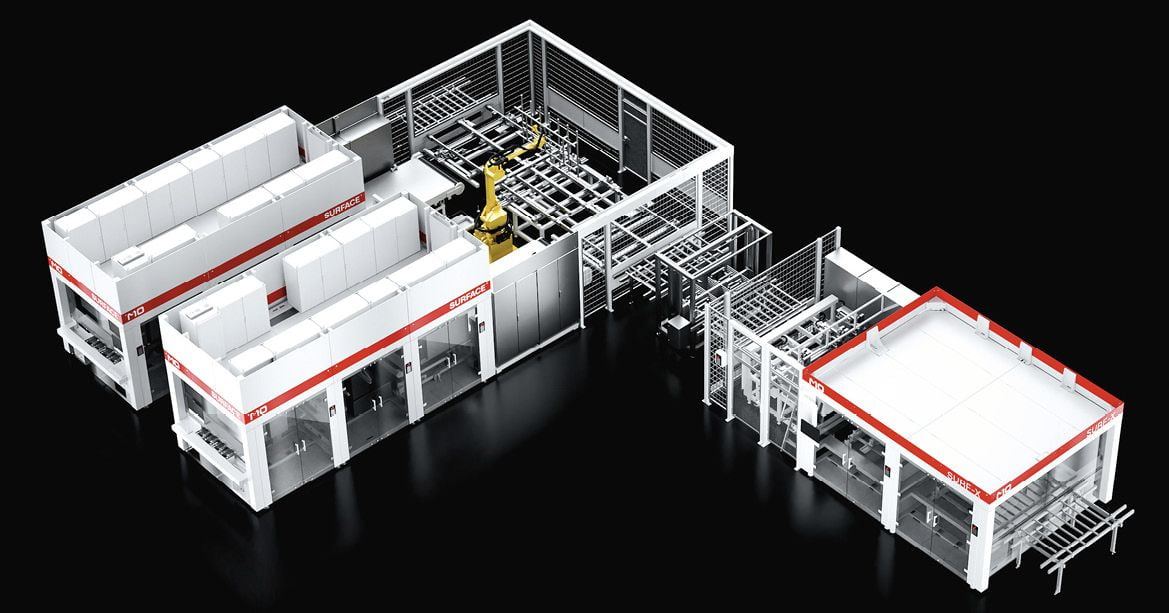

In late 2021, M10 Industries, a German manufacturing gear provider, and the Fraunhofer Institute for Photo voltaic Power Techniques, a analysis physique, first printed particulars of their shingled cell matrix know-how. After a improvement interval of simply seven months, the 2 companions have been in a position to current a manufacturing software prepared for collection manufacturing, which they named Floor.

This resulted within the 2021 basis of M10 Photo voltaic Gear GmbH, a three way partnership established by M10 Industries and Zahoransky, an automation gear provider, to start manufacturing Floor machines for large-scale, business PV cell interconnection, on the JV facility in Freiburg, Germany.

The potential is large. The stringer system is the world’s first – and thus far, solely – series-built wiring machine for shingle matrix photo voltaic modules that locations and connects shingled cells in an offset sample throughout the face of a module. , much like the best way bricks are laid. exterior the wall. The same old method of connecting the cells – the place they’re aligned vertically and related as a thread – is changed by a way the place the cell strips are positioned inside and related in order that they overlap whereas being offset vertically. Electrons movement throughout the floor of the ensuing module matrix, each in collection and in parallel.

Specifically constructing facades, the shingled cell matrix methodology exhibits its energy. The know-how produces aesthetically interesting modules with out gaps between cells and likewise presents sturdy shading tolerance to spice up efficiency. Because the manufacturing machine was launched – able to processing 12,000 cell strips of any dimension per hour – on the Intersolar Europe commerce present final 12 months, M10 Photo voltaic has attracted curiosity from varied PV producers. A manufacturing unit is in service on the M10 website to assist potential clients within the improvement and manufacturing of prototype modules.

Matrix simulation

Through the machine’s improvement section, the accountable events requested themselves if it may course of 12,000 cell strips per hour of operation and, in that case, if that was the restrict. What ranges of shaking and climbing can be real looking, colleagues requested.

Philipp Zahn and Marco Saladin are significantly within the solutions. As joint managing administrators, the pair is accountable for the destiny of the M10 Photo voltaic Gear enterprise. A specialist in mechanical engineering and automation, the Zahoransky enterprise has labored with Siemens for a few years and the know-how corporations are collaborating once more on the Floor innovation course of.

“We began the simulations about 10 years in the past, which may be very uncommon for a medium-sized enterprise,” mentioned Saladin, who beforehand labored for Zahoransky. As a substitute of losing years on desk calculations or trial-and-error loops, the enterprise depends on simulation packages for early engine ideas.

The managers selected Siemens’ Tecnomatix Plant Simulation software program, which Zahoransky was already acquainted with. The software program simulates complicated manufacturing methods and processes in easy-to-understand pc fashions and is used to simulate, visualize, analyze, and optimize manufacturing and logistics processes.

“We have been in a position to make quick and dependable choices and consider completely different eventualities early within the improvement section of Floor,” Saladin mentioned. “Plant simulation helps us design the structure, management logic, and useful resource measurement.” Saladin and Zahn consider they’ve achieved time financial savings of round 30% over the course of the challenge, due to the simulations.

“With the plant simulation, we will simply discover the perfect design for our interconnection system and likewise obtain the utmost throughput,” Zahn mentioned. This shortens the preliminary manufacturing section and eliminates time-consuming and costly correction steps later within the manufacturing course of.

trade in Europe

With its new Floor software, M10 is pondering far exterior the field for PV module manufacturing and appears to play an essential function in bringing giant scale PV manufacturing again to Europe. “If we need to make a giant contribution to Europe’s power transition, we have to revive PV manufacturing right here at house,” Saladin mentioned. “Our experience in analysis, product improvements, and traditionally sturdy mechanical engineering shall be of nice assist.”

Explanation for the climate

“It’s finally a matter of progress whereas rebuilding the whole worth chain – regardless of the difficulties within the provide chains, regardless of the worth will increase, and regardless of the geopolitical uncertainties certainty,” Zahn mentioned. Germany, and the remainder of Europe and the world, at present rely closely on China for the availability of photo voltaic cells, modules, and associated elements. “In Europe, our energy is in new manufacturing ideas. We have to develop them,” mentioned Saladin. This implies gigawatt-scale factories. “At this scale, simulations are important,” he added. “They develop into a very powerful software for a quick begin at a practical value.”

pv journal print version

The following situation of pv journal celebrates China’s journey from photo voltaic new entrant to putting in greater than 100 GW(AC) of panels this 12 months – Vincent Shaw and Frank Haugwitz take into account the exceptional 20-year journey. We have a look at what Indonesia wants to attain its net-zero ambitions and likewise discover the sparks of a photo voltaic renaissance in Europe, by means of commerce exhibits and gigafatory planning.

Plant simulation is commonly utilized in full line ideas to optimize throughput, get rid of bottlenecks, and reduce stock. To research the consequences of various manufacturing variations, simulation fashions take into account inner and exterior provide chains, manufacturing assets, and enterprise processes. On the similar time, they’ll test completely different line management methods and synchronize the primary and auxiliary traces. Plant simulation can outline complicated materials movement guidelines and monitor line efficiency.

Efficiency simulation

In addition to Tecnomatix, Siemens presents a whole portfolio of options for the whole worth chain – from polysilicon manufacturing and ingot reducing to cell manufacturing and module manufacturing. Built-in options for photo voltaic panel producers and plant and machine builders embrace every thing from energy provide to plant-wide automation.

The objective is all the time environment friendly, versatile, and sustainable manufacturing of top-quality photo voltaic panels. The M10 stringer system is step one, and the remaining will observe.

In regards to the writer: Tobias Wachtmann Turned head of Siemens’ world glass and photo voltaic enterprise in Karlsruhe, Germany, since June 2020. The 47-year-old started his profession on the firm in 2000. After coaching in industrial know-how, he occupied gross sales roles at Siemens earlier than transferring to the method trade headquarters in Karlsruhe in 2012. Since 2017, he has labored in vertical glass and photo voltaic, specializing in account improvement.

The views and opinions expressed on this article are these of the writer, and don’t essentially mirror these held by pv journal.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].