MIT engineers have developed ultralight material photo voltaic cells that may rapidly and simply flip any floor into an influence supply.

These robust, versatile photo voltaic cells, that are thinner than a human hair, are glued to a robust, mild material, which makes them straightforward to put in on a hard and fast floor. They’ll present vitality whereas strolling as a wearable energy fabric or be transportable and quickly deployed to distant areas for help in emergencies. It’s one hundredth the burden of standard photo voltaic panels, generates 18 instances extra energy-per-kilogram, and is made out of semiconducting inks utilizing printing processes that may be scale sooner or later to create massive areas.

As a result of they’re skinny and lightweight, these photo voltaic cells will be laminated to many various surfaces. For instance, they are often built-in into the sails of a ship to supply energy whereas at sea, connected to tents and tarps deployed in catastrophe restoration operations, or utilized to the wings of drones to increase their flight. This light-weight photo voltaic expertise will be simply built-in into constructed environments with minimal set up wants.

“The metrics used to judge a brand new photo voltaic cell expertise are sometimes restricted to their energy conversion effectivity and their dollar-per-watt value. Simply as necessary is integrity — the straightforward to make use of new expertise. Light-weight photo voltaic materials will be built-in, which gives vitality for immediately’s work. We try to speed up the adoption of photo voltaic, due to immediately’s pressing have to -deploy new carbon-free vitality sources,” stated Vladimir Bulović, the Fariborz Maseeh Chair in Rising Know-how, head of the Natural and Nanostructured Electronics Laboratory (ONE Lab), director of MIT.nano, and senior writer of a brand new paper describing the work.

Becoming a member of Bulović on the paper are co-lead authors Mayuran Saravanapavanantham, {an electrical} engineering and laptop science graduate scholar at MIT; and Jeremiah Mwaura, a analysis scientist on the MIT Analysis Laboratory of Electronics. The analysis is printed immediately in Small Strategies.

Slowed down by photo voltaic

Conventional silicon photo voltaic cells are fragile, so that they should be encased in glass and encased in heavy, thick aluminum framing, which limits the place and the way they are often deployed.

Six years in the past, the ONE Lab crew produced photo voltaic cells utilizing a brand new sort of thin-film materials so mild they may sit on high of a cleaning soap bubble. However these ultrathin photo voltaic cells are made utilizing advanced, vacuum-based processes, which will be costly and difficult to scale up.

On this work, they started to develop thin-film photo voltaic cells which can be totally printable, utilizing ink-based supplies and scalable manufacturing strategies.

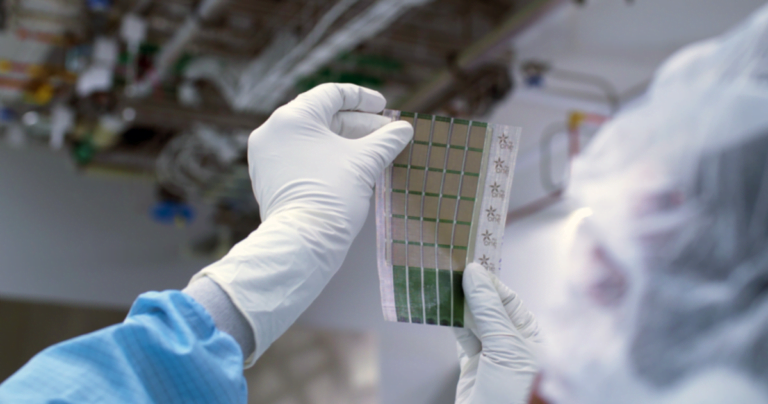

To make photo voltaic cells, they use nanomaterials within the type of a printable digital inks. Working in MIT’s nano clear room, they coated the photo voltaic cell construction utilizing a slot-die coater, which deposited layers of digital supplies onto a ready-made, releasable substrate. which is barely 3 microns thick. Utilizing display printing (a method just like how designs are added to silkscreened T-shirts), an electrode is positioned on the construction to finish the photo voltaic module.

The researchers can peel the printed module, which is about 15 microns thick, from the plastic substrate, which is able to turn into an ultralight photo voltaic gadget.

However such skinny, freestanding photo voltaic modules are difficult to deal with and break simply, making them troublesome to deploy. To resolve this problem, the MIT crew looked for a light-weight, versatile, and high-strength substrate that they may adhere the photo voltaic cells to. They recognized materials as the most effective answer, as a result of they supply mechanical energy and suppleness with little additional weight.

They discovered an excellent materials – a composite material weighing solely 13 grams per sq. meter, commercially referred to as Dyneema. This material is manufactured from fibers so robust that they have been used as ropes to carry the sunken cruise ship Costa Concordia from the underside of the Mediterranean Sea. By including a layer of UV-curable glue, which is only some microns thick, they adhere the photo voltaic modules to the sheets of this material. This types an ultra-light and mechanically robust photo voltaic construction.

“Though it seems easier to only print the photo voltaic cells instantly on the material, this can restrict the selection of attainable materials or different receptive surfaces to be chemically and thermally suitable in all steps of processing required to make the gadgets. Our strategy decouples the manufacturing of the photo voltaic cell from its ultimate integration,” defined Saravanapavanantham.

Greater than standard photo voltaic cells

After they examined the gadget, MIT researchers discovered it may generate 730 watts of energy per kilogram when freestanding and about 370 watts-per-kilogram when deployed on high-strength Dyneema material, which is about 18 instances extra power-per-kilogram than standard photo voltaic cells.

“The typical rooftop photo voltaic set up in Massachusetts is about 8,000 watts. To generate the identical quantity of energy, our photovoltaics material would solely add about 20 kilograms (44 kilos) to the roof of a home,” he stated.

Subscribe for counter-intuitive, shocking, and impactful tales delivered to your inbox each Thursday

Additionally they examined the sturdiness of their gadgets and located that, even after rolling and unfolding a material photo voltaic panel greater than 500 instances, the cells nonetheless retained greater than 90 p.c of their preliminary energy technology capabilities.

Whereas their photo voltaic cells are lighter and extra versatile than conventional cells, they should be encased in a special materials to guard them from the atmosphere. The carbon-based natural materials used to make the cells will be modified by interacting with moisture and oxygen within the air, which might impair their efficiency.

“Encapsulating these photo voltaic cells in heavy glass, as is the case with conventional silicon photo voltaic cells, would scale back the price of present growth, so the crew is presently creating ultrathin packaging options that provides little to the burden of immediately’s ultralight gadgets,” stated Mwaura.

“We’re working to take away as a lot of the non-solar-active materials as attainable whereas sustaining the shape issue and efficiency of those ultralight and versatile photo voltaic buildings. For instance, we all know that the manufacturing course of will be extra which will be streamlined by printing on releasable substrates, equivalent to the method we use to create the opposite layers of our gadget. This may facilitate the interpretation of this expertise to the market,” he added.

This analysis was funded, partly, by Eni SpA by way of the MIT Power Initiative, the US Nationwide Science Basis, and the Pure Sciences and Engineering Analysis Council of Canada.

Reprinted with permission from MIT Information. Learn the unique article.