Passive solar module cooling tech based on paraffin wax – pv magazine International

Researchers in Egypt used paraffin wax as a phase-change materials (PCM) to cut back the working temperature of PV modules. They discovered that the fabric improves energy output by greater than 15%, in comparison with a reference module with out cooling.

The researchers of Sohag College in Egypt developed a passive cooling system for photo voltaic panels that makes use of a PCM referred to as paraffin wax RT-42.

PCMs can absorbs, shops and releases quite a lot of latent warmth in an outlined temperature vary and is commonly used, on the analysis degree, for cooling the PV module. Paraffin wax is obtained from petroleum by dewaxing mild lubricating oil shares and is commonly utilized in candles, wax paper, polishes, cosmetics, and electrical insulators.

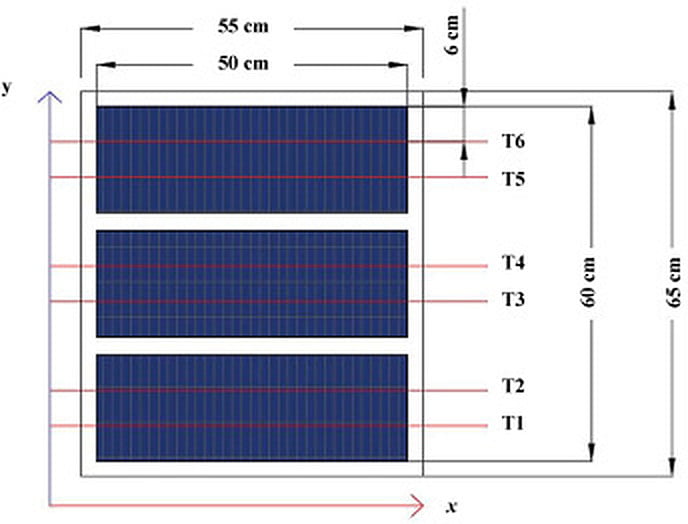

The scientists put in the cooling system on a 40 W polycrystalline panel with a dimension of 55 cm × 65 cm and in contrast its efficiency with the identical reference panel with out cooling. They examined panels with tilt angles of 15, 20, 25, and 30 levels and with totally different PCM thicknesses.

Each modules have an effectivity of 16.5%, an open-circuit voltage of 12 V, a short-circuit present of 4.3 A, and a fill issue of 0.78.

“To accommodate the PV panels, an oblong PCM container with inside dimensions of 55 cm × 65 cm x 4 cm made of two mm thick galvanized sheet was used,” the group defined. “The container is hooked up to the again facet of the PV panel and wrapped with a silicon adhesion to forestall doable leakage if the PCM is totally melted.”

The lecturers measured the temperature distribution on the entrance floor of the PV panels in several sections utilizing an infrared digicam. Through the experiment, they noticed that, for all PCM thicknesses, rising the lean angle of the panel reduces the floor temperature. “

“When the PV-PCM panel is put in at an angle of 15 levels, it data the very best temperature distribution over the panel floor, whereas the bottom temperature is recorded for the floor of the photo voltaic panel at a tilt angle of 30 levels,” they careworn. “That is in all probability attributed to the truth that the power stream contained in the PCM resulting from convection could be very low when the lean angle is small.”

The cooled panel, when put in with a tilt angle of 30 levels, achieved an influence yield of 15.8% greater than the reference module with out cooling.

“Altering the angle of inclination from 15 levels to 30 levels improves {the electrical} effectivity of PV-PCM with 3 cm thickness by 7.4%,” the scientists mentioned. “Lastly, the usage of PCM with a thickness of three cm will increase {the electrical} effectivity of the PV-PCM panel by 14.4% in comparison with the PV reference panel.”

The scientists didn’t present details about the price of the proposed know-how and its use in business manufacturing. They describe the passive cooling method in “Bettering the efficiency of PV panels utilizing part modification materials (PCM): An experimental implementation,” just lately revealed in Case Research in Thermal Engineering.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].