Battery supply chain state of health – pv magazine International

Because the US Uyghur Compelled Labor Prevention Act reveals, corporations prepared to spend huge on batteries danger being blindsided by supply-chain-related legal guidelines. Listed below are some tips about how US builders can anticipate coverage curveballs.

Lithium-ion batteries can retailer power from distributed sources equivalent to photo voltaic and wind technology, including crucial flexibility to an more and more dynamic electrical grid. However whereas the way forward for the storage business is vibrant with the brand new freestanding tax credit introduced by the Inflation Discount Act, so is the highlight on world battery provide chains.

The expertise of the PV business presents a cautionary story: A latest report from the US commerce physique the Photo voltaic Vitality Industries Affiliation discovered tightening commerce rules, designed to deal with the labor considerations within the PV provide chain, contributed to a 23% decline in US photo voltaic installations final 12 months in comparison with the earlier 12 months. with 2021.

Coverage switch

An business can adapt to such shifting insurance policies, but it surely takes time, particularly with so many shifting components. Anticipating and making ready for the long run coverage panorama, together with the environmental, social, and company administration necessities of finish prospects, shall be crucial to realizing the total potential of the storage business.

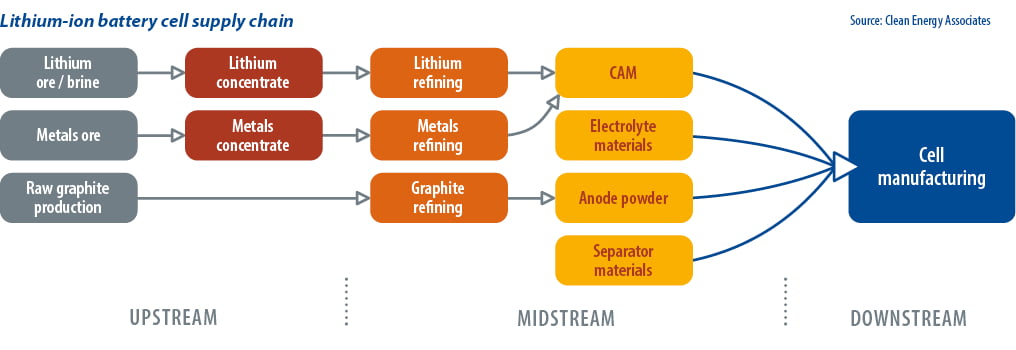

Whereas commerce insurance policies within the photo voltaic provide chain focus on one ingredient – silicon – navigating the upstream lithium-ion battery provide chain is an order of magnitude extra difficult. In North America, electrical car batteries sometimes use nickel-manganese-cobalt (NMC) chemistry, whereas stationary storage functions sometimes use the much less energy-dense lithium iron phosphate (LFP) chemistry.

NMC and LFP cells encompass a number of sub-components, such because the cathode, anode, and electrolyte, every of which has its personal a number of materials provide chains. Essential supplies equivalent to graphite, lithium carbonate, copper, and aluminum all require various ranges of mining and processing and should go by means of a number of international locations earlier than ending up in a utility scale storage facility or electrical car. Given the complexity, what can consumers do to arrange for higher scrutiny of their provide chain and to enhance accountability?

Code of conduct

Potential regulation and rising shopper consciousness put extra duty on battery sellers and consumers to determine transparency in how, and with whom, they do enterprise. Step one as a purchaser is to obviously outline the insurance policies of company social duty by creating a code of conduct. It ought to set clear requirements for matters equivalent to labor practices, stakeholder engagement, and environmental affect mitigation. A corresponding code of conduct must also be developed for suppliers. By codifying the corporate’s values and mission up entrance, the suitable tone for conversations with suppliers may be set.

Companies that don’t have a company duty program to tell the creation of codes of conduct ought to create one. This ensures that their authorised vendor checklist is proscribed to suppliers that align with their group’s values. Two good assets for this are the ISO 26000 steerage on social duty, and the accountable sourcing guidebook drafted in 2021 by commerce physique the US Vitality Storage Affiliation.

As soon as a code of conduct is developed, applicable language needs to be included in provide agreements. The phrases of the provision offers ought to be certain that the code of conduct applies to the provider in addition to to your entire provide chain, for all parts. The language used needs to be binding and supply clear treatments if sub-suppliers don’t comply. Further language, guaranteeing cooperation with different supply-chain-related requests – equivalent to entry to services and provide chain mapping – must also be included.

Provide chain mapping

Mapping a battery provide chain is crucial to establish potential dangers, as monitoring supplies on the mine stage clearly identifies all taking part suppliers. This stage of visibility allows consumers to establish which sub-suppliers could also be at higher danger of not complying with their code of conduct.

The complexity of the battery provide chain and the potential resistance of sub-suppliers to sharing this data made mapping difficult. To facilitate identification, it’s useful to first deal with sub-components with higher danger or with restricted manufacturing areas, and to pay much less consideration to supplies which are produced worldwide in giant portions, for instance copper and aluminum.

The significance of audits

After negotiating for extra transparency and entry, and mapping the provision chain, it is very important confirm that suppliers are literally following their contractual obligations. Processes in place and provider qualification procedures needs to be reviewed and validated to make sure that the customer’s code of conduct is applied in observe, somewhat than simply on paper.

Earlier than the search turns into extra difficult, there’s a golden alternative now to include extra accountability into battery provide chains. Taking proactive steps to align buying with firm values can pay dividends when new insurance policies inevitably take form.

This may current distinctive challenges relying on the scale of the companies. A small firm could discover it harder to vary suppliers’ practices than a big one. Actually, the coordination of uniform practices will finally use the business’s collective bargaining energy to push suppliers towards higher transparency. The easy steps outlined above, in the meantime, can construct resilience to potential coverage adjustments and meet shopper demand for accountable merchandise.

Concerning the authors: Raiene Santana an affiliate engineer at CEA. Santana has six years of expertise within the photo voltaic business, and helps CEA purchasers in provide chain monitoring and ESG. He beforehand held roles in power engineering and worldwide affairs at ENG3 and the Photo voltaic Vitality Industries Affiliation (SEIA), respectively. He holds a grasp’s diploma in power effectivity from the Federal College of Espirito Santo.

Andreas Savva is an utility engineer, power storage, with CEA. Savva has 5 years of expertise in battery analysis and improvement, together with in depth expertise in lithium-ion and alkaline zinc battery chemical compounds. He holds an MS in supplies science and engineering from Boise State College and a BS in chemical engineering from NJIT.

The views and opinions expressed on this article are these of the creator, and don’t essentially mirror these held by pv journal.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].