Scientists from Fraunhofer ISE goal to make use of epitaxially grown p-type silicon wafers in TOPCon rear emitter (TOPCore) photo voltaic cells with the goal of decreasing manufacturing prices and carbon footprint. They declare that this mix paves the best way for TOPCore units with greater than 25% effectivity.

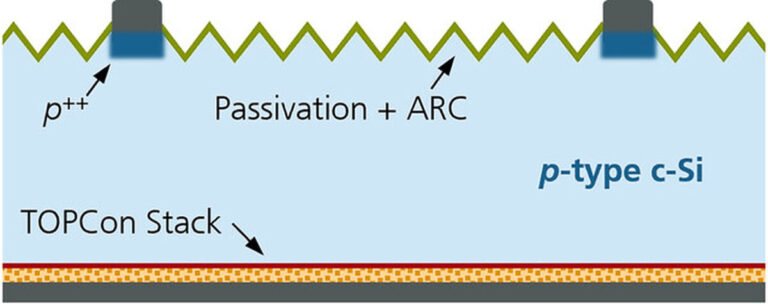

Germany’s Fraunhofer Institute for Photo voltaic Power Methods (ISE) proposes the usage of epitaxially grown p-type silicon wafers in TOPCon rear emitter (TOPCore) photo voltaic cells, combining tunnel oxide passivated contact (TOPCon) expertise in a rear emitter as an alternative of the entrance. – facet pn junction.

Epitaxially grown p-type wafers, additionally referred to as “EpiWafers,” provide a low-cost and low-carbon materials for photo voltaic cells, offering increased voltages and cost elements. in comparison with cells with a front-side gathering emitter.

Epitaxially grown p-type wafers, additionally referred to as “EpiWafers,” provide a low-cost and low-carbon materials for photo voltaic cells, offering increased voltages and cost elements. in comparison with cells with a front-side gathering emitter.

The scientists grew p-type Cz-Si wafers with a resistivity of two.5 Ω cm and a diameter of 150 mm by means of a chemical vapor deposition (CVD) batch reactor at atmospheric strain. They then chemically cleaned and passivated the wafers with a floor passivation layer made from aluminum oxide (Al2O3) deposited by plasma-assisted atomic layer deposition (ALD) at 180 C for 78 cycles, leading to 10 nm thick layers on either side.

“The ensuing pattern set consists of EpiRef wafers with a ultimate thickness of 110 μm and three completely different base resistivities of three, 14, and 100 Ω cm,” they stated.

Making use of the entrance finger grid design to all EpiRef wafers, the staff noticed that every of the three units might probably obtain energy conversion effectivity exceeding 25%. Additionally they famous that the presence of iron (Fe), chromium monoboride (CrB), and Boron (BO) defects in EpiWafers didn’t have an effect on cell efficiency, indicating the prime quality and purity of epitaxially grown wafers.

“In our case, these structural defects, originating from epitaxial development, may be averted through the use of a unique susceptor design,” the teachers stated. “Structural defect-free areas protect their wonderful materials high quality throughout high-temperature processing.”

They introduced a novel method for making “Epitaxially Grown p-type Silicon Wafers Prepared for Cell Efficiencies Exceeding 25%,” which was just lately revealed by RRL Photo voltaic.

In April 2021, Fraunhofer ISE stated it had achieved an effectivity of 26.1% for a TOPCore photo voltaic cell.

“Based mostly on a scientific simulation-based evaluation, we have been in a position to derive some basic design guidelines for future high-efficiency silicon photo voltaic cells with higher than 26% effectivity,” Stefan Glunz, division director of photovoltaics analysis at Fraunhofer ISE, stated on the time. “Two-sided contacted photo voltaic cells have the potential to attain efficiencies of as much as 27 p.c and thus surpass the earlier world report for silicon photo voltaic cells.”

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.