Two Norwegian firms have designed floating concentrating photovoltaic thermal know-how that produces each electrical energy and warmth. It’s meant for use in carbon seize initiatives and supported by an industrial warmth pump system.

Norway-based analysis firm Sintef and Norwegian floating PV specialist Svalin Photo voltaic are presently creating a floating concentrating photovoltaic thermal (CPVT) receiver meant to be used in carbon seize services. .

“The power requirement required for CO2 stripping might be essentially the most dominant issue governing solvent-based post-combustion extraction know-how,” Sintef’s Senior Enterprise DeveloperMartin Bellmann, spoke pv journal. “Primarily, any know-how that may considerably cut back the so-called reboiler obligation – power consumption for CO2 elimination – is very wanted.”

The 2 firms describe the brand new know-how as a solar-assisted carbon seize system that in entire or partially generates the thermal power wanted for fuel separation.

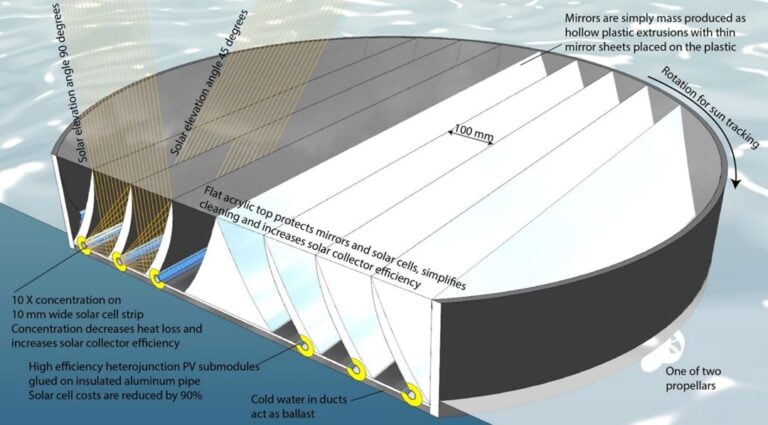

“The proposed CPVT design is a single-axis monitoring system of the ‘linear via’ sort, the place rows of curved mirrors are mechanically rotated in order that the size route of the mirrors is all the time parallel to coincidental daylight and follows the each day movement of the solar,” added Bellmann. “Focus ratios of about 10 days could be achieved.”

The CPVT receiver is predicated on a tube with photo voltaic cell strains hooked up to it. The small space of the CPVT receiver permits for using high-efficiency PV cells. “Though these PV cells are dearer, the price could be offset by lowering the realm required,” explains Bellmann. “Typical crystal silicon and multi-junction cells must be thought-about. Afterwards, the price-to-performance ratio will probably be evaluated when the prototype is accomplished and operating and we’ve got collected sufficient knowledge from the check trials.

In keeping with Sintef, the environment friendly thermal administration of the CPVT receiver is achieved by the warmth switch fluid surrounding the tubes. The chilly fluid enters the pipe community on the inlet which collects the warmth from the receiver and retains the PV cells at a low temperature. The collected warmth is then transferred to a high-temperature warmth pump (HTHP), which acts as an auxiliary thermal power booster that upgrades waste warmth and low-temperature warmth from the receiver for steam manufacturing. within the Carbon Seize Storage (CCS) course of.

{The electrical} energy produced by the PV cells could be equipped to the grid or used on to energy the HTHP or different auxiliary processes within the CCS course of.

Sintef is presently engaged on the design and growth of the Svalin Photo voltaic plant and plans to buy the parts and construct a pilot facility in the summertime of 2024. “Initially, the plant will probably be examined on dry land as a part of present carbon seize facility operated by Sintef in Tiller, simply exterior Trondheim, “mentioned Bellmann. “To realize a cost-efficient design of the CPVT system, you will need to perceive if the annual power manufacturing, each thermal and electrical, can compensate for the extra prices of set up, monitoring and upkeep. “

The demonstrator will probably be a part of the EU-funded undertaking “Remodeling energy-intensive course of industries by integrating power, course of, and feedstock flexibility” (TRINEFLEX), with a complete finances of € 19.3 million ($ 21.2 million) and consists of 28 companions.

Some Sintef researchers have lately developed a floating construction for offshore PV, a a high-temperature industrial warmth pump that may work with pure water as its work medium, and a floating photo voltaic platform to be used in aquaculture initiatives.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.