Foldable, textured silicon wafers for flexible heterojunction solar cells – pv magazine International

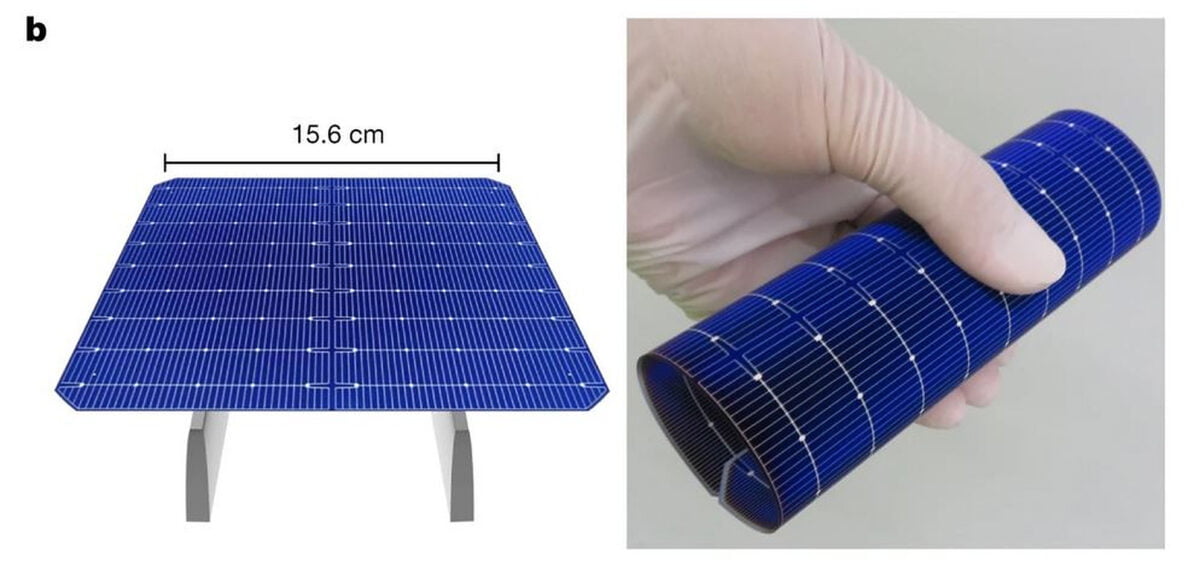

A 15.6 cm × 15.6 cm versatile SHJ photo voltaic cell

Picture: Chinese language Academy of Sciences, nature, Artistic Commons License CC BY 4.0

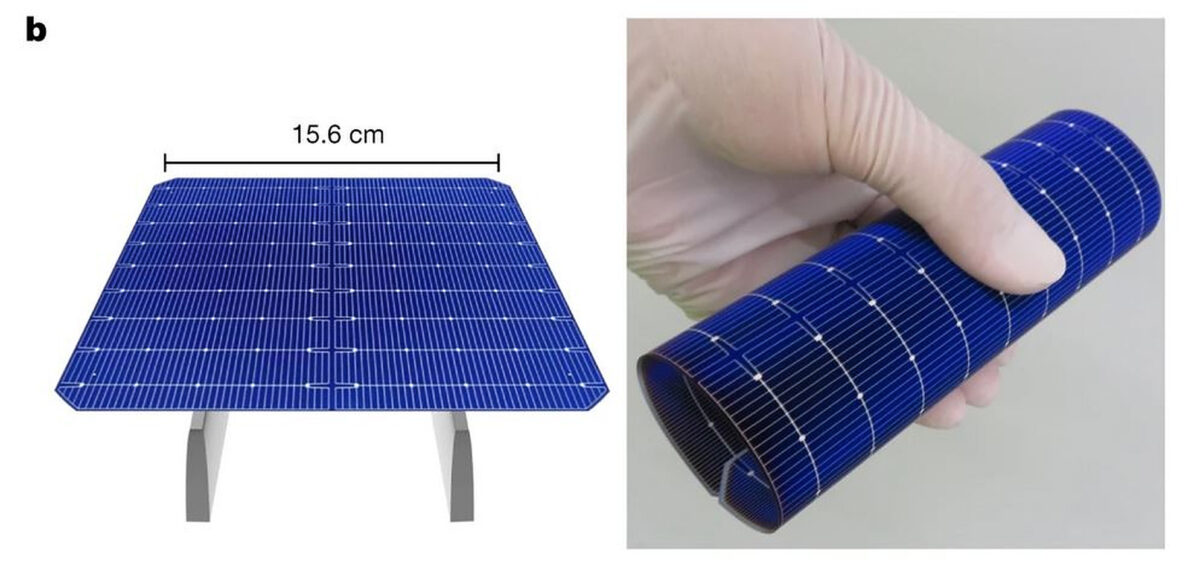

Researchers on the Chinese language Academy of Sciences have efficiently developed foldable crystalline silicon (c-Si) wafers, recognized for his or her robust light-harvesting functionality, to be used in versatile silicon heterojunction (HJT) photo voltaic cells.

Scientists say that the HJT cell know-how is good for the manufacturing of versatile photo voltaic cells, as a result of it removes the sting warping attributable to inner stress through the firing course of. The wafers are made utilizing a blunting therapy, a way generally used to spherical the sides of wafers, to stop flashing and cracking throughout processing. The researchers mentioned that the therapy resulted in a shift within the fracture mechanism from intrinsic brittle cleavage fracture to shear banding with steps and cracks.

The analysis workforce used 180 μm Czochralski n-type c-Si wafers, equipped by China-based Sichuan Yongxiang, to create textured wafers with a thickness of 60 μm.

“The wafers had been textured with a 2.1-vol% aqueous alkali resolution at 80 C for 10 min to type microscale pyramids on the surfaces,” it defined. “All wafers are cleaned utilizing a typical root trigger evaluation (RCA) course of to take away natural and metallic ions. Subsequent, they had been cleaned with a 2.0% aqueous resolution of hydrofluoric acid for 3 minutes to etch the floor oxide.

The lecturers used the wafers to make two HJT cells with thicknesses of 65 μm and 55 μm. The primary cell has an influence conversion effectivity of 23.31%, an open-circuit voltage of 0.752 V, a short-circuit present density of 0.09 mA cm-2, and a fill issue of 82.40%. The second cell achieved an effectivity of 23.35%, an open-circuit voltage of 0.754 V, a short-circuit present density of 0.11 mA cm-2and a fill issue of 82.51%.

The workforce then utilized an anti-reflective coating based mostly on magnesium fluoride (MgF2) to the cells and their effectivity was elevated to 24.50%.

“Though this worth is decrease than (25.83%) of a thick cell as a result of it’s affected by the low gentle harvesting capacity of the thinner wafer, it’s a exceptional effectivity in comparison with the present versatile photo voltaic cells constructed from different cost-effective supplies,” the scientists mentioned, noting that utilizing a 60-μm wafer would scale back manufacturing prices by roughly 29%. “Total, the versatile know-how developed on this research lowered the extent of vitality prices by roughly 39% (23%) on the photo voltaic cell (module) stage.

The lecturers introduced a brand new manufacturing course of for “Versatile photo voltaic cells based mostly on foldable silicon wafers with blunted edges,” just lately printed in NATURE. The analysis workforce contains scientists from Tongwei (TW), Changsha College of Science and Expertise, Southwest Petroleum College, Soochow College, and Beihang College,

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].