South Korean scientists have developed a selective palladium composite membrane on a porous metallic help to chop the ammonia content material of the permeated hydrogen stream. Dutch researchers, then again, current two options to this technique – rising the thickness of the chosen layer of the membrane, or utilizing a unit to purify the permeate of the membranes.

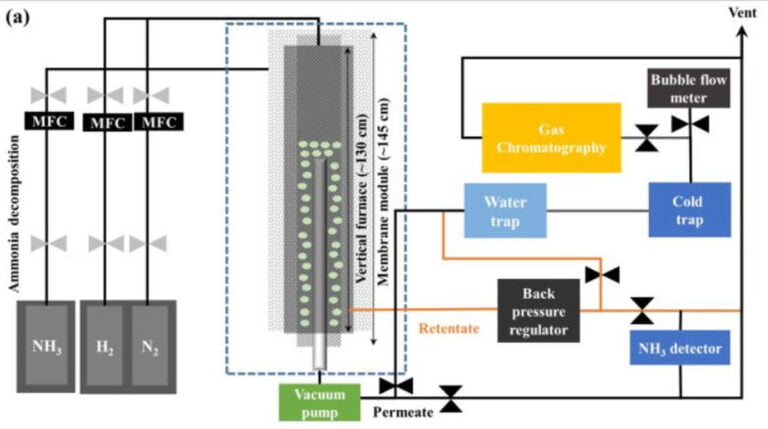

Korea Institute of Vitality Analysis scientists have developed a pretreatment technique for the porous metallic help of a extremely selective palladium (Pd) composite membrane for ammonia decomposition. The purity of hydrogen (H2) produced utilizing membrane reactor tech just isn’t all the time excessive sufficient to immediately feed H2 to gas cells, so methods are wanted to cut back the ammonia (NH3) content material of the absorbed hydrogen stream. . South Korean researchers utilized alumina Sol, a secure colloidal answer made from boehmite, to a yttria-stabilized zirconia (YSZ) crammed porous Inconel help. “A vacuum-assisted, two-step electroless plating of Pd drastically will increase the hydrogen selectivity,” the researchers stated in a latest paper in power. They utilized a extremely selective Pd composite membrane in a membrane reactor with a Ru/Al2O3 catalyst to provide high-purity hydrogen via ammonia decomposition. The Pd composite membrane reactor can selectively seize hydrogen, will increase the ammonia conversion fee and high-purity hydrogen manufacturing via a one-step response coupled with purification. They stated the membrane reactor was capable of obtain excessive ammonia conversion (99.6%) and excessive hydrogen purity (99.99%), with a hydrogen manufacturing fee of 0.25 Nm3 h−1 at 745 Ok and a gauge strain of 500 kPa.

Eindhoven College of Expertise, then again, presents two alternative routes to extend the purity of the hydrogen produced in a membrane reactor for the decomposition of ammonia – by rising the thickness of the chosen membrane layer, or utilizing a membrane permeate purification unit. They are saying the thickness of the membrane is greater than 6 micrometer (µm) on ultra-pure hydrogen could be obtained at pressures under 5 bar. Their research, revealed in Worldwide Journal of Hydrogen Vitality, exhibits that Pd-based membranes degrade when uncovered to temperatures above 500 C. “A less expensive answer, nevertheless, consists of utilizing an adsorption mattress on the backside of the membrane reactor,” the researchers wrote. “Extremely-pure hydrogen could be achieved at greater reactor pressures, decrease temperatures and thinner membranes, leading to decrease reactor prices.”

ACWA Energy signed a $7 billion take care of two Thai state-owned firms to provide inexperienced hydrogen. ACWA Energy, PTT Public Firm Ltd. (PTT), and the Electrical energy Producing Authority of Thailand (EGAT) will conduct an funding feasibility research for the proposed inexperienced hydrogen and derivatives tasks. They goal to provide about 225,000 tons of inexperienced hydrogen per 12 months, SAYS ACWA Energy.

HDF Vitality and US Worldwide Improvement Finance Corp. (DFC) agreed to help the event of inexperienced hydrogen vegetation in Indonesia. The amenities will use HDF Vitality’s know-how, Renewstable, which mixes renewable sources and mass. The French firm stated that DFC’s technical help will help feasibility research for its pipeline of twenty-two Renewstable tasks in Indonesia, for an funding of $1.5 billion, supported by growth establishments.

Rolls-Royce and EasyJet claims to have taken “the world’s first run of a contemporary hydrogen aero engine.” The businesses performed floor checks in the UK utilizing a transformed Rolls-Royce AE 2100-A regional plane engine and hydrogen generated by renewables within the Orkney Islands. “After analyzing this early floor check idea, the partnership plans a collection of extra rig checks main as much as a full floor check of a Rolls-Royce Pearl 15 jet engine, ” WRITES the automaker.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.