Indian startup offers nanocoating to improve solar module output – pv magazine International

Picture: Trinano Applied sciences

From pv journal India

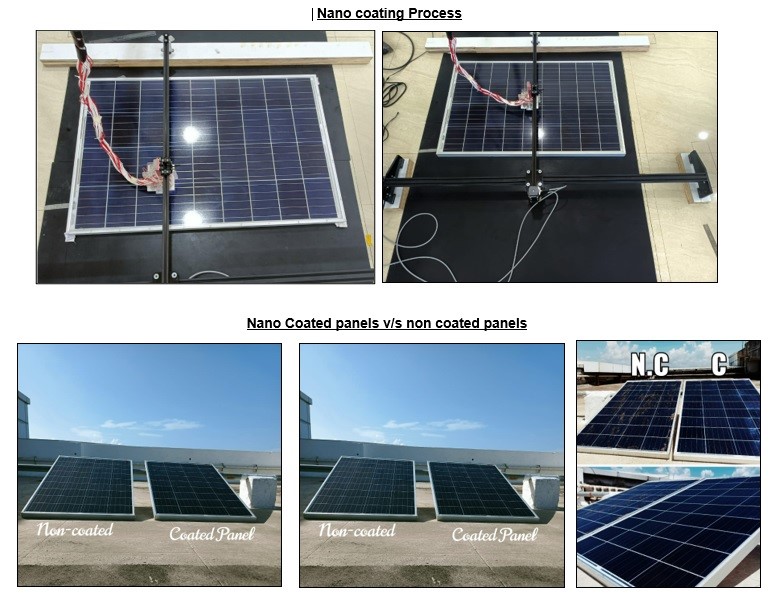

India’s Trinano Applied sciences has developed nanocoatings for photo voltaic modules that may enhance their energy output by as much as 4% and decrease temperatures by as much as 3 C in comparison with non-coated panels.

“Because of this a ten MW solar energy plant with nanocoated panels will generate a further energy of 720 MWh and thus a further revenue,” mentioned Trinano Applied sciences CEO Harsh Sethi. pv journal.

Nanocoating is environmentally pleasant and chemically secure. It’s designed to enhance gentle trapping, anti-reflection, and self-cleaning properties.

“Moreover growing the vitality output of the panel, it helps in anti-soiling and decreasing potential-induced degradation (PID). The coating can final for greater than 5 years and cut back panel upkeep and cleansing (particularly water-based) prices,” mentioned Sethi, noting that the Thus, the return on funding is about two years.

Nanocoatings have undergone intensive testing at analysis universities and labs in India and Thailand, confirming enhancements in panel output and temperature on the Nationwide Middle for Photovoltaic Analysis and Training (NCPRE), IIT Bombay, with know-how and R&D collaboration with the USA’s Nationwide Renewable Vitality Laboratory, Fraunhofer in Germany, and the College of New South Wales in Australia.

Comparable outcomes have been noticed on the Nationwide Institute of Photo voltaic Vitality (NISE) in Gurugram, in addition to pilot tasks carried out by Toyota’s rooftop photo voltaic mission in Mumbai, a residential rooftop photo voltaic plant in Navi Mumbai, and a Tata Energy pilot mission. in Bengaluru.

The patent software for the know-how has been submitted by India and different nations which are members of the Patent Cooperation Treaty (PCT), with expectations that it will likely be granted in 2023.

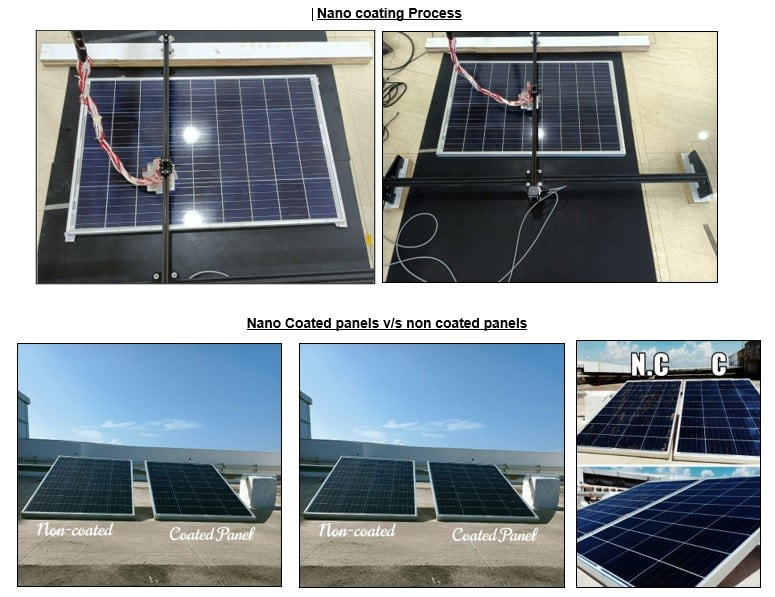

The coating course of, carried out utilizing a transportable coating machine and 6 kg frames, permits for the applying of present panels with out eradicating them from service. It includes solid-phase deposition with out using liquid. In distinction, industrial coatings, made from natural supplies, are liquid and utilized utilizing paint, brush, or spray strategies, however they decompose and deteriorate inside two years.

Nanocoatings are appropriate for monocrystalline, polycrystalline, and thin-film photo voltaic panels in ground-mount and rooftop functions. Potential clients embody photo voltaic panel producers and photo voltaic plant homeowners.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].