Chinese language researchers have developed a kesterite PV system utilizing a clear fluorine-doped tin oxide (FTO) substrate as a substitute of substrates based mostly on opaque Mo-coated soda lime glass. The cell has an open-circuit voltage of 0.522 V, a short-circuit present of 33.0 mA cm−2, and a fill issue of 68.55%.

Scientists from Nanjing College of Posts and Telecommunications in China made a skinny movie kesterite (CZTSSe) photo voltaic cell that makes use of a clear electrode.

Kesterite is likely one of the most promising mild absorber materials candidates for potential use in low-cost thin-film photo voltaic cells. Kesterites embody widespread parts comparable to copper, tin, zinc, and selenium. In contrast to CIGS compounds, no provide bottlenecks are anticipated sooner or later.

Nonetheless, kesterite is much less efficient than CIGS in mass manufacturing. The world file for such cells is 12.6%, which was achieved by the Japanese skinny movie producer Photo voltaic Frontier in 2013.

“Our cell can be utilized in building-integrated photovoltaics (BIPV) and agrivoltaics, in addition to photo voltaic home windows and facades,” mentioned researcher Hao Xin. pv journal.

The researchers constructed the cell through the use of a clear fluorine-doped tin oxide (FTO) coated substrate. molybdenum (Mo) as a substitute of generally used substrates based mostly on opaque Mo-coated soda lime glass. In addition they added amolybdenum trioxide (MoO3) layer between the FTO and the precursor movie to stop the expansion of grains on the absorber floor.

As well as, researchers depend on sodium (Na) doping and silver (Ag) alloying to speed up grain progress. They dissolve the absorber’s compound in a dimethyl sulfoxide (DMSO) resolution.

“The answer is painted on the FTO substrate to kind the precursor movie, which is additional combined with selenium in a furnace tube to kind the CZTSSe absorber,” the scientists defined. “Then the cadmium sulfide (CdS) buffer layer is deposited on CZTSSe via chemical tub deposition.

Lecturers too positioned a window layer of intrinsic zinc oxide (i-ZnO) and indium tin oxide (ITO) by sputtering. They end the manufacturing course of by thermal evaporation of nickel (Ni) and aluminum (Al) floor electrodes.

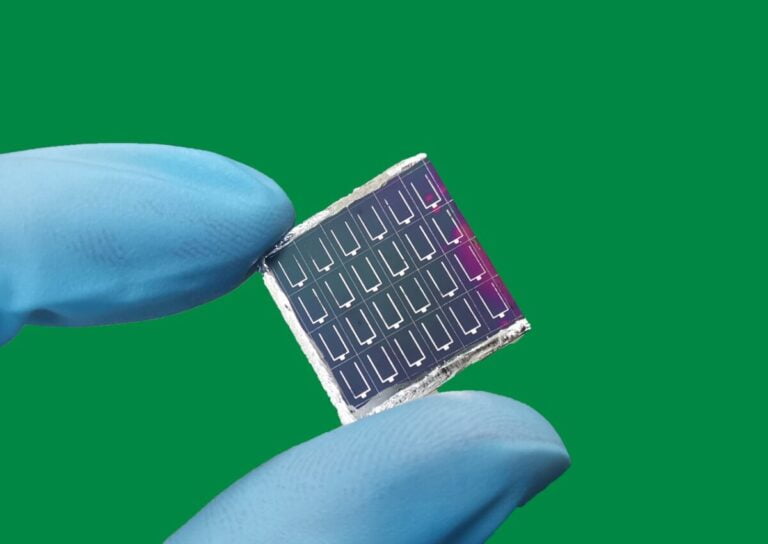

Underneath normal illumination circumstances, a cell with an lively space of 0.103 cm2 and an antireflective coating based mostly on magnesium fluoride (MgF2) achieves an influence conversion effectivity of 11.43%, an open-circuit voltage of 0.522 V. It has a short-circuit present of 33.0 mA cm−2 and a fill issue at 68.55%. in China Nationwide PV Trade Measurement and Testing Heart of Fujian Metrology Institute (FJL) confirmed the outcomes.

“The tall one effectivity and facile resolution technique of kesterite photo voltaic cells in clear electrodes reported right here open the door for this inexperienced and low cost skinny movie expertise in lots of superior functions, comparable to semitransparent, bifacial, and tandem photo voltaic cell,” the scientists concluded.

The researchers launched the cell tech in “11.4% Effectivity Kesterite Photo voltaic Cells on Clear Electrode,” which was lately printed in Superior Vitality Supplies. “In the meanwhile, we have now not estimated the price of manufacturing of the cells, however we’re positive that the uncooked supplies concerned within the manufacturing of the cell itself are very low cost,” they mentioned.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.