Midsummer and researchers from the College of California, Los Angeles (UCLA), say that their new tandem PV cell is appropriate for the corporate’s Duo manufacturing gear, which produces 56 mm x 156 mm CIGS cells on a versatile chrome steel substrate.

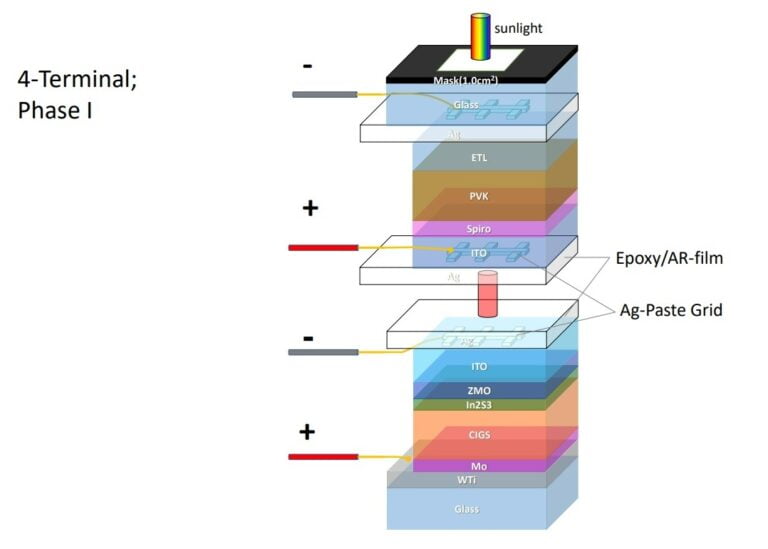

UCLA researchers and Midsummer, a Swedish building-integrated PV (BIPV) module producer, declare that there proven a 4 terminal (4T) tandem photo voltaic cell. It’s primarily based on an higher cell made from perovskite and a decrease cell primarily based on copper, indium, gallium and selenium (CIGS).

“The cell primarily based on a perovskite floor cell that’s optimized for integration with Midsummer’s CIGS cells used of their industrial suite of BIPV merchandise,” stated Midsummer, with out revealing any further technical particulars. “Analysis continues with the aim of a two-terminal perovskite-CIGS cell that may make this explicit photo voltaic cell which is extra aggressive and appropriate for mass manufacturing.”

The producer says that the tandem cell is appropriate for Duo manufacturing gear, which manufactures 56 mm x 156 mm CIGS cells in a versatile chrome steel substrate.

UCLA set an preliminary effectivity file for such tandem cells in 2018, at 22.4%. This surpasses the 17.8% effectivity achieved in 2016 by a collaboration of European analysis institutes, which created a perovskite/CIGS mini-module measuring 3.76cm².

US researchers designed the underside cell with an indium zinc oxide (IZO) clear conductive oxide movie, a tin(IV) oxide (SnO2) buffer layer, a perovskite layer, and a layer on methyl-substituted carbazole (Me-4PACz) as a hole-transport layer. For the highest cell, they used an indium tin oxide (ITO) substrate, a cadmium sulfide (Cds) layer, and a CIGS absorber.

Yang Yang, a professor of supplies science at UCLA, stated on the time that units with related designs may attain efficiencies above 30%.

“We really feel lucky to be working with Professor Yang’s workforce at UCLA to have exhibits vital progress in perovskite,” stated Leon Chiu, president of Pioneer Supplies, which is a key provider for the compound sputtering goal utilized in Midsummer’s novel processing for CIGS in chrome steel. “Midsummer’s manufacturing integration proved to be CIGS processing with Yang’s Lab tailored perovskite exhibits a transparent path to the enlargement of reaching BIPV by enhancing effectivity and decreasing prices.”

Midsummer at present operates a 50 MW manufacturing facility in Bari, southern Italy, and one other manufacturing facility in Sweden. In 2020, it launched a 500 W photo voltaic panel for a lot of rooftops.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.