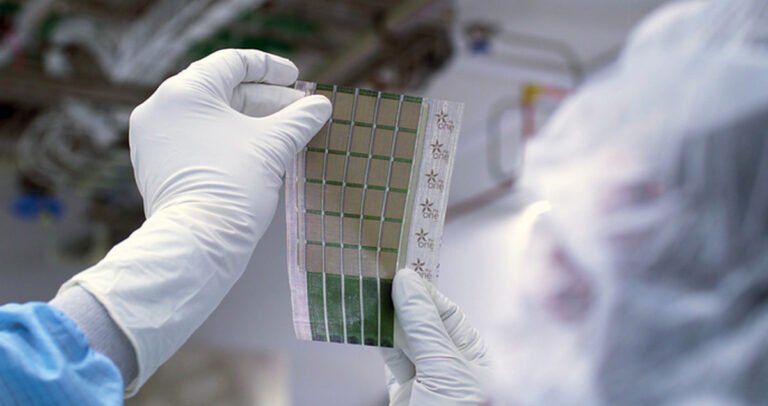

US researchers have developed a skinny movie natural photo voltaic module on a vapor-deposited releasable substrate made from parylene. The gadget can be utilized as a wearable, or to convey photo voltaic technology to distant areas.

The scientists of The Massachusetts Institute of Expertise (MIT) has developed absolutely printed, large-area natural photovoltaic (OPV) modules that can be utilized as wearable energy material or deployed in distant areas for emergency response.

“It is one hundredth the burden of standard photo voltaic panels, generates 18 instances extra energy-per-kilogram, and is made out of semiconducting inks utilizing scalable printing processes sooner or later to the creation of huge areas,” the researchers mentioned, noting that thin-film gadgets may be laminated to many alternative surfaces. “Extremely-thin PVs may be ready on premade substrates resembling plastic movies and metallic foils, or on in-situ shaped substrates resembling chemical vapor-deposited parylene or solution-processed polyimide.”

The US group constructed module cells with vapor-deposited parylene because the in-situ shaped releasable substrate, a hole-transporting materials (HTM) based mostly on PEDOT:PSS, a molecular donor-acceptor pair often known as PV2000:PC60The BM provided by Taiwan’s Raynergy Tek, and coated with nanowire movies of seven.7 nm, with the deposition of tin-oxide nanoparticles, acts as an electron transport layer.

“The photoactive layer of PV2000:PCBM is coated, adopted by the hole-transporting PEDOT:PSS layer,” the scientists defined. “A comparatively thick layer of gap transporting materials is coated on high of the lively layer to offer enough safety from the mechanically abrasive screen-printing means of the silver high electrode.”

They constructed built-in fabric-PV modules with a selected energy of 370 W kg-1weight of 105 gm-2and free-standing gadgets with a selected energy of 730 W kg-152 grams-2.

“Normally, the efficiency of the ultra-thin gadget is corresponding to gadgets made immediately on glass apart from a discount in short-circuit present attributed to the discount of transmission from the method change between the -house deposition of the clear electrode in comparison with these bought commercially. deposited immediately on the glass, “they mentioned, as the present purple decreases the delamination as a result of some wrinkling of the free-standing movie. “Such small gadget checks present sufficient assist to proceed additional growth of the manufacturing course of for bigger OPV modules.”

They introduced new natural cell tech in “Printed Natural Photovoltaic Modules on Transferable Extremely-thin Substrates as Additive Energy Sources,” which was just lately printed in Small Strategies.

“Necessary to completely notice the potential of this work, is the provision of the identical ultra-lightweight encapsulation obstacles that may shield the lively layers of the textile-PVs from publicity to the environment, which in flip can prolong the operational life of those gadgets, as wanted for real-world functions,” they concluded.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].