German scientists have found a polymer compound that, when added to perovskite thin-film precursor supplies, wraps itself across the perovskite crystals, appearing as a cushion to guard the perovskite construction from thermomechanical stress . They use the additive to provide cells with as much as 24.6% effectivity, which retain 96% of their preliminary efficiency after a fast take a look at equal to 1 yr within the subject.

Scientists led by Germany’s Helmholtz-Zentrum Berlin (HZB) have developed an additive for perovskite supplies, which seems to behave as a ‘cushion’, defending the extra delicate perovskite crystals from stress-induced to vary in temperature.

The workforce additionally added to the listing of HZB achievements – together with the 32.5% effectivity document for a perovskite-silicon tandem cell – by creating perovskite cells utilizing a pin structure that achieved a document -setting 24.6% effectivity. This structure is inherently extra strong, however usually much less environment friendly, than the generally used nip design.

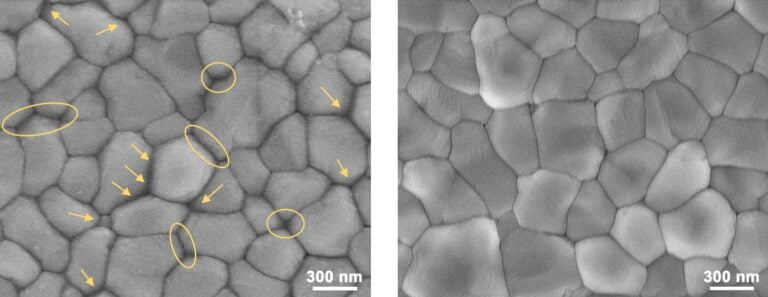

“Daylight can warmth the within of a PV cell to 80 Celsius; at midnight, the cell then shortly cools right down to the surface temperature,” defined HZB Professor Antonio Abate. “This causes nice mechanical stress on the skinny layer of perovskite microcrystals, which creates defects and even native section transitions, in order that the skinny movie loses its high quality.”

The group discovered that working with a polymer compound it calls v-pV2F (full title b-poly(1,1-difluoroethylene) can additional enhance the steadiness of the pin photo voltaic cell.

“This polymer appears to wrap the person perovskite microcrystals in a skinny movie like a smooth shell, making a sort of cushion in opposition to thermomechanical stress,” defined Abate.

Perovskite photo voltaic cells made with this additive have been subjected to varied assessments, the outcomes of which seem within the paper. Science.

Cells measuring 18 mm² reached a most effectivity of 24.6%, whereas bigger 1 cm² units achieved 23.1%. The cells are subjected to greater than 100 temperature cycles between 80 C and -60 C, in addition to 1,000 hours of steady illumination – which HZB says is equal to nearly a yr of outside use .

These cells retain 96% of their preliminary efficiency after 1000 hours of simulated daylight at 25 C, and 88% when the take a look at is carried out at 75 C. Along with its cushion impact, the additive has been proven to enhance cell effectivity by affecting cost provider transport, permitting the group to set a pin machine effectivity document.

HZB will now work to scale back efficiency loss over time nonetheless, to a stage that may be thought of acceptable in business units.

“Even below this excessive stress, they nonetheless achieved 96 % effectivity in the long run. It is in the precise order of magnitude,” mentioned Abate. “Whether it is now potential to scale back the losses just a little extra, the perovskite photo voltaic modules will nonetheless be capable of produce most of their authentic output after 20 years – this aim is sort of reached.”

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.