Picture: Lee et al, Superior Vitality Supplies, CC by 4.0 Artistic Commons License CC BY 4.0

The mixing of lithium steel into lithium-ion batteries, to switch the graphite that’s generally used immediately because the anode materials, might be a serious step ahead in vitality storage expertise that may enable an enormous leap in capability. in battery and efficiency. However lithium steel is a tough materials to work with, and its tendency to kind “dendrite” buildings that department out from the anode and trigger quick circuits has restricted progress.

Researchers are pursuing totally different methods to beat the problem posed by lithium steel, and a staff led by the Gwangju Institute of Science and Know-how and Jeonbuk Nationwide College in South Korea has proposed a technique that seems to supply a number of benefits. . The group is working with carbon fiber paper as a substitute for the copper foil generally used to kind the lithium steel anode construction.

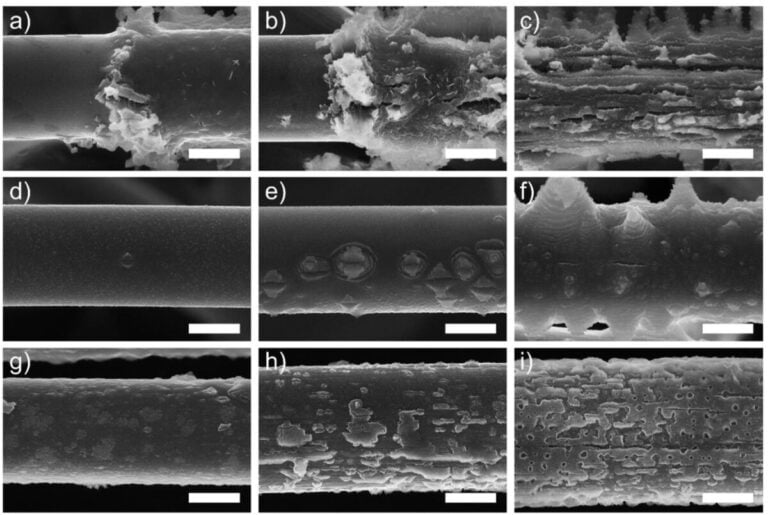

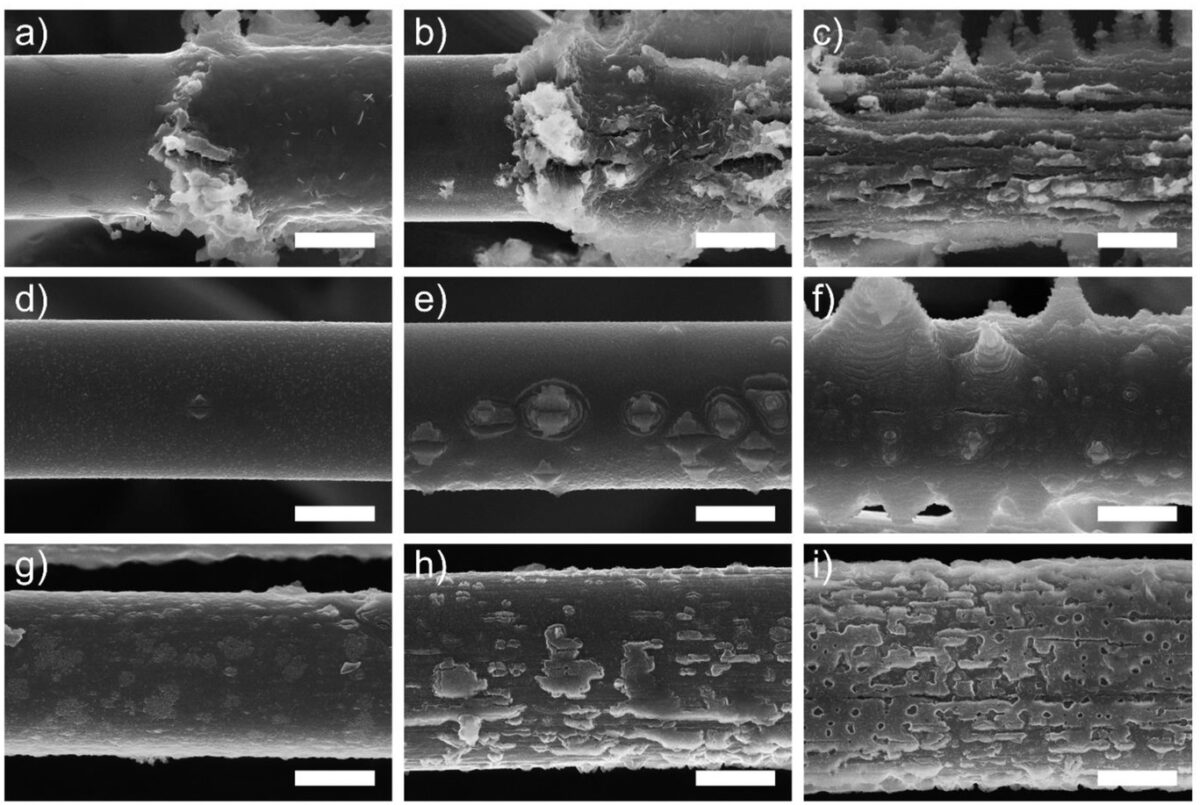

The group ready carbon fiber with polymer binders and used a 3D framework on which lithium steel was positioned. The preparation is described in full within the paper Development of Hierarchical Surfaces in Carbon Fiber Paper for Lithium Metallic Batteries with Superior Stability, lately revealed in Superior Vitality Supplies.

Batteries developed utilizing a carbon fiber/lithium steel anode achieved a excessive particular vitality of 428 Wh/kg.

“Contemplating the 5 instances decrease density and decrease price of carbon fiber in comparison with copper, our proposed anode materials is a vital breakthrough that may speed up the commercialization of sturdy and light-weight lithium steel batteries,” stated Sung-Ho Lee, head of the Carbon Composite Analysis Middle on the Korea Institute of Science and Know-how.

Additional testing confirmed that in biking, the lithium coated the carbon fiber with out the formation of dendrites because of the formation of an inorganic stable electrolyte interphase layer. Full battery cells made with anodes keep 85% of their preliminary capability after 300 cycles. The group says it plans to proceed engaged on this methodology, which can present a simplified answer to combine lithium-metal into vitality storage.

“We consider that our superior technique, which differs from beforehand reported applied sciences, comparable to including novel and poisonous components to electrolytes and altering floor morphology utilizing advanced strategies, will allow realization of a steady LMA with excellent electrochemical efficiency for utility in sensible fields of vitality storage to switch standard LiBs,” the group concluded.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.