Bold targets for photo voltaic power era current challenges to an trade desperate to discover new methods for photo voltaic manufacturing. Neil Spannchief govt of UK skinny movie photo voltaic producer Energy Roll, described a business resolution to the issues of over-reliance on silicon photo voltaic modules.

As photo voltaic turns into a bigger proportion of the power combine, there’s a downside with the dominance of silicon in panel manufacturing. Silicon accounts for 95% of the 14 GW of photo voltaic module era capability put in within the UK. That photo voltaic fleet gives simply 4% of the UK’s power wants. The federal government’s 2022 power technique requires a fivefold enhance in photo voltaic capability, to 70 GW, by 2035. Nonetheless, silicon photo voltaic’s view of an extra 56 GW presents a major moral, financial, and safety implications and that prospect drives analysis into alternate options, which is the place perovskites are available in.

Manufacturing silicon panels is dear and sophisticated and, because the UK doesn’t have vital silicon photo voltaic manufacturing capability, we’ll proceed to depend on imports. Because the world has discovered of late, the geographical focus of worldwide provide chains presents challenges to power safety and logistics. Manufacturing photo voltaic panels has a excessive carbon footprint and the typical carbon payback interval for a silicon photo voltaic panel – the size of time a panel should generate electrical energy earlier than it cancels carbon emissions included in its manufacturing – sitting for 300 days to 350 days.

Additionally, the hardness and bulk of silicon photo voltaic panels typically restrict their utility to ground-mounted photo voltaic farms and set up on load-bearing roofs. For instance, one gigawatt of photo voltaic era capability requires about 2.5 million panels. To realize the 70 GW wanted by 2035, an enormous land seize. No surprise the Worldwide Power Company is asking for diversification of photo voltaic PV manufacturing.

Is perovskite the reply?

There has lengthy been curiosity within the potential use of perovskite for solar energy era, because of the superconducting and digital properties noticed within the crystal, which is present in abundance within the Earth’s mantle. The truth that cheaply out there perovskite has distinctive properties for absorbing gentle photons to create an electron stream and generate electrical energy positions the fabric as an excellent candidate to exchange silicon in photo voltaic era. .

With a lot curiosity in perovskites, enthusiastic producers are on the lookout for new methods to include them into PV manufacturing and my firm, Energy Roll, isn’t any exception. We now have patented a method that makes use of perovskites on a versatile, light-weight substrate: polyethylene terephthalate (PET) – an industrial thermoplastic sheet. The PET substrate is embossed with small v-shaped channels or “microgrooves” no multiple or two microns vast.

Roll-to-roll

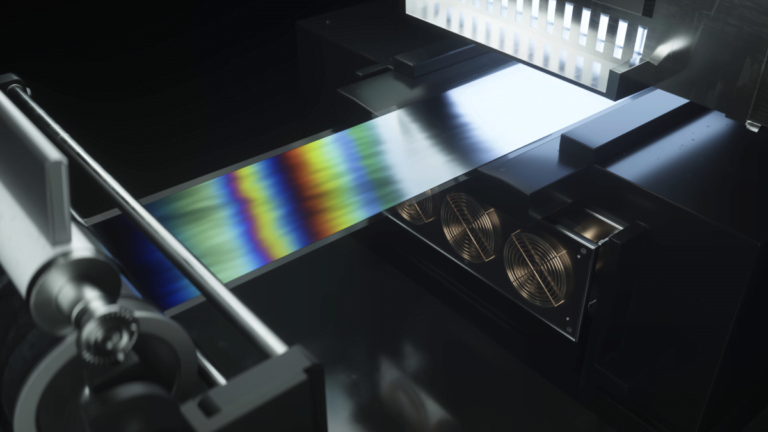

The microgrooves are printed with excessive precision on heat-strengthened PET utilizing a roll-to-roll course of. They create conductive pathways designed to optimize the stream of electrons and “tune” {the electrical} output of the photo voltaic module. The partitions of the microgrooves are coated with metals, because the electrodes, adopted by an oxide layer that acts because the electron transport layer (ETL) and gap transport layer (HTL). Perovskite ink is printed into grooves on prime of the ETL/HTL layers to create an ultra-thin, versatile photo voltaic cell, or “photo voltaic movie” that’s 100 instances thinner than silicon photo voltaic panels.

Roll-to-roll manufacturing is a straightforward and scalable course of that’s utilized in different low-cost sectors reminiscent of packaging, and is the important thing to the low value of photo voltaic movie. Importantly, it skips many manufacturing steps concerned in different versatile PV applied sciences.

After perovskite ink coating and annealing – the latter a heating course of to help pliability – a strain adhesive barrier movie is utilized to the floor in a steady course of to guard the crystallized perovskite. Further barrier movies and a foil again sheet might be utilized utilizing strain or vacuum lamination.

To analysis cost-to-strength ratios, Energy Roll carried out weekly checks on numerous barrier movies and forms of lamination uncovered to outside situations over the previous six months. . It exhibits that movies with excessive cost-barrier and vacuum lamination don’t present efficiency degradation whereas these with low cost-barrier and strain lamination are affected by the contents. Additional testing is underway.

The Energy Roll methodology produces perovskite PV with manufacturing prices 5 instances cheaper – and a carbon payback interval as much as ten instances shorter – than conventional silicon photo voltaic panels.

Extensive utility

The mix of microgrooves and perovskite produces a versatile, light-weight, environment friendly photo voltaic movie at a fraction of the price of silicon photo voltaic panels. The versatile nature and easy set up course of signifies that perovskite photo voltaic movie might be put in in conditions the place silicon photo voltaic panels can’t be deployed. For instance, it may be built-in into home windows, blinds, autos, low-load bearing roofs, and vertical surfaces. Whereas photo voltaic panel farms take up a whole lot of inexperienced area, perovskite PV can make the most of areas already developed for business or home use.

The biggest marketplace for photo voltaic movie is on business and industrial roofs. Only a quarter of the UK’s 2.5 billion sq. meters of south-facing roofs might generate 30% of the UK’s power wants. Perovskite PV photo voltaic movie might be put in in non-structural rooftop area cheaply and at scale, serving to the UK meet its power safety and net-zero targets.

And the alternatives for light-weight photo voltaic movie lengthen past the UK. The manufacturing course of is definitely replicable and might be licensed worldwide, to assist speed up the deployment of photo voltaic power. With lower than 2% of worldwide rooftops internet hosting photo voltaic installations, there’s a enormous alternative for light-weight, low-cost perovskite PV. The photo voltaic movie is flexible and has the potential to be built-in on rooftops and on totally different surfaces. This may assist enhance entry to wash power era in areas of the world that at the moment lack any vital renewable infrastructure. Perovskite PV is predicted to hit the market as quickly as subsequent 12 months, with wider adoption by 2025, and guarantees to revolutionize the photo voltaic sector.

The views and opinions expressed on this article are these of the writer, and don’t essentially mirror these held by pv journal.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.