Accelerating the transition in direction of renewable supplies and sustainable processes for printed natural digital units is crucial for a inexperienced round financial system. Presently, the manufacturing of natural electronics with aggressive performances is linked to poisonous petrochemical-based solvents with giant carbon emissions.

By changing the solvents used of their manufacture, natural photo voltaic cells will be made extra environmentally sustainable. Researchers at KAUST (King Abdullah College of Science and Expertise) have proven that plant-based solvents can change non-renewable, environmentally hazardous solvent counterparts with out affecting the results of capturing mild in photo voltaic cells.

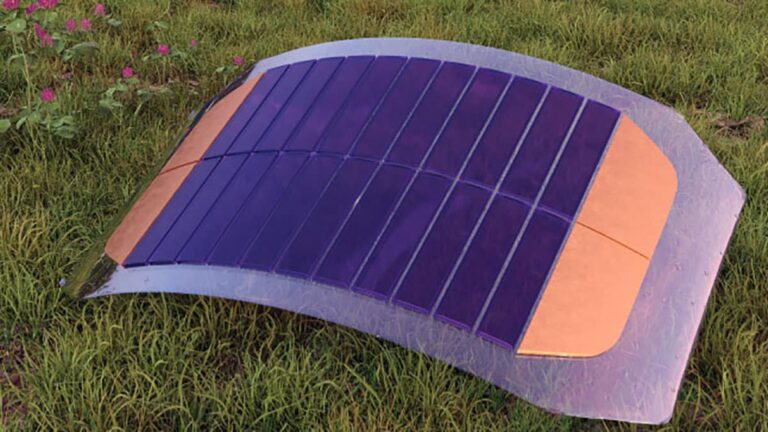

Natural photovoltaics (OPVs) are among the many greenest photo voltaic cell applied sciences, contributing as little as three grams of CO.2 equal carbon emissions per KW of vitality.

“Nonetheless, their manufacturing nonetheless depends on halogenated solvents which, along with being linked to reproductive and most cancers dangers, are derived from petrochemical processes,” mentioned Daniel Corzo, a Ph.D. pupil in Derya Baran’s lab, who led the work. “We wish to discover inexperienced options to guard the well being and security of employees when these cells are produced on a bigger scale and to additional cut back the carbon footprint of OPVs.”

Since solvents are the idea of the printable inks used within the manufacturing of natural photo voltaic cells, they’re important within the manufacturing of OPV. “These inks require lively natural supplies that stay in answer throughout processing after which crystallize beneath optimized situations because the ink dries,” Corzo mentioned. “The selection of solvent has a major affect on OPV processing and total system efficiency.”

Utilizing the Hansen solubility ink formulation framework, the researchers recognized potential different solvents and investigated the efficient movie formation and drying mechanisms required for optimum cost transport. This technique is common for state-of-the-art supplies in OPVs, light-emitting diodes (OLEDs), and field-effect transistors (OFETs).

“This technique measures how related molecules are to one another primarily based on their molecular interactions,” Corzo defined. “You possibly can select solvents which are the identical on the molecular stage however have useful properties, together with diminished toxicity, or from renewable sources.”

The strategy confirmed that plant-based solvents known as terpenes – a gaggle that features the fragrant oils eucalyptol and limonene – may very well be appropriate substitutes. These solvents will be obtained from plant residues, akin to eucalyptus leaves or orange peel, or will be produced from algae and microorganisms in bioreactors, the researchers defined.

As potential carbon-negative solvents, solvent blends primarily based on these substances have confirmed to be very nicely fitted to OPV manufacturing. “We’ve got obtained photo voltaic cells with efficiencies of greater than 16 p.c utilizing terpene-based inks – the identical as chlorinated solvents – however with an 85 p.c decrease carbon footprint and with the potential to be carbon detrimental in coming,” Corzo mentioned.

The workforce created an interactive library for inexperienced solvent picks and made it publicly obtainable by way of the OMEGAlab web site. “We imagine that many industries and tech builders will profit from terpene solvent improvement,” Baran added. “This library can transcend the usage of inexperienced solvents for natural electronics as a result of terpenes are additionally used within the meals and fragrance industries, for instance.”

Journal reference:

- Daniel Corzo, Diego Rosas-Villalva, Amruth C, Guillermo Tostado-Blázquez, Emily Bezerra Alexandre, Luis Huerta Hernandez, Jianhua Han, Han Xu, Maxime Babics, Stefaan De Wolf, and Derya Baran. Excessive-performing natural electronics utilizing terpene inexperienced solvents from renewable feedstocks. Pure Vitality, 2022; DOI: 10.1038/s41560-022-01167-7