Reusing silicon from end-of-life photovoltaic modules for battery anodes – pv magazine International

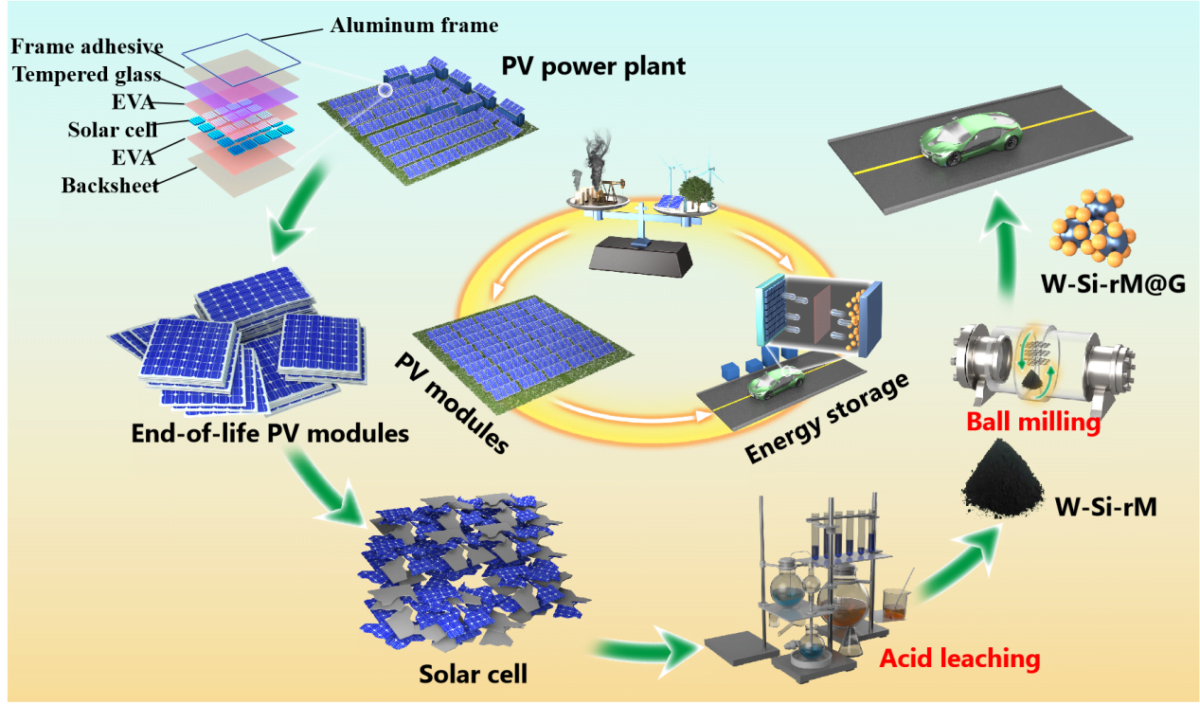

Chinese language scientists are proposing to make use of recycled silicon from discarded photo voltaic cells to make anodes for batteries. They mixed recycled waste silicon powder with graphite and created a composite materials that’s claimed to exhibit excellent electrochemical efficiency.

Scientists led by China’s Kunming College of Science and Expertise have proposed reusing silicon from discarded photo voltaic cells to supply silicon-carbon composite anode supplies that can be utilized in battery anodes.

“The aim of our work is to suggest a easy and efficient recycling technique geared toward realizing extra reuse of silicon supplies in end-of-life PV modules,” the lead analysis creator, Shaoyuan Li, stated. pv journal. “In keeping with present typical technical strategies comparable to acid and alkali leaching, one ton of end-of-life PV modules can recuperate 40 kg of silicon materials, producing a internet revenue of $104.9. If the recycled that silicon materials is mixed with graphite utilizing a easy ball milling course of to acquire a silicon-carbon composite anode, it generates a revenue of $1,883.

To check “Excessive-performance silicon carbon anodes based mostly on value-added recycling technique of end-of-life photovoltaic modules,” printed in powerthe researchers defined that the waste silicon powder (W–Si) wanted for battery anodes was obtained by pulverizing photo voltaic cell fragments utilizing a vibration mill.

The cells had been then mechanically disassembled from the modules after which lower into 6 mm x 6 mm items. These fragments are then soaked in a toluene resolution for twenty-four hours to dissolve the ethylene vinyl acetate (EVA) encapsulant. “To additional take away EVA, the cell fragments wrapped in EVA had been positioned in a tube furnace for pyrolysis at 550 C for two hours below an argon ambiance,” they stated. “Deionized water and ethanol are used for ultrasonic cleansing a number of instances to get photo voltaic cell fragments.”

With these fragments, the analysis staff developed waste silicon powder by combining recycled silicon with graphite utilizing a easy ball-milling course of. The ensuing composite materials, known as [email protected]has been reported to exhibit outstanding electrochemical efficiency.

“It has an preliminary discharge capability of as much as 1,770 mA hg-1maintains particular capability of 913 mA hg-1 after 200 cycles of a present density of 500 mA g-1and the typical Coulombic effectivity reached 98.99%, which is just a 0.24% capability loss,” Li defined, saying that the usage of graphite creates a buffer house for increasing the quantity of silicon, which improves the biking power of the fabric. “Graphite has good contact with silicon particles, and the introduction of graphite has tremendously improved {the electrical} conductivity of the silicon materials.”

Trying forward, the scientists stated extra work is required to determine a full and environment friendly value-added recycling trade for end-of-life PV modules, highlighting the present difficulties in organising worthwhile companies on this sector with out public assist. “Recycling end-of-life PV modules has sure financial feasibility, however it isn’t economical sufficient to take care of the graceful operation of a enterprise,” they stated.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].