From pv journal 03/23

The brand new 400 W-plus shingled photo voltaic modules are in the marketplace, serving the necessity for high-powered, extra sturdy, modern all-black merchandise. The Chinese language cell big Tongwei is answerable for new modules – its Terra sequence launched in 2022. The Terra sequence is out there in energy lessons of 400 W to 430 W, with efficiencies from from 20.1% to 21.7%.

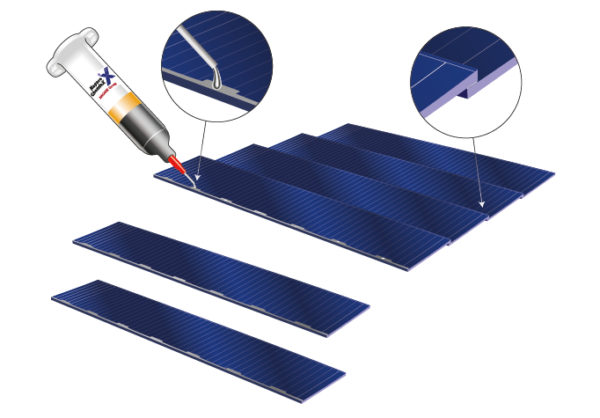

Tongwei is famend as a serious provider in China that adopts shingling, which entails reducing photo voltaic cells into strips which are then joined collectively by electrically conductive adhesive (ECA), barely overlapping alongside the size of the cell. edge.

The top of Tongwei’s shingled module division, Yan Li, mentioned that shingled merchandise provide “benefits in energy, effectivity, and reliability” and technical benefits because of “high-density packaging and versatile interconnection.”

“Nevertheless, we imagine that the vary of Terra high-efficiency shingled modules with an aesthetic look will goal sure markets, and improve our share and model affect within the residential phase,” Li mentioned. . Together with lovely aesthetics and power, shingling additionally offers sturdiness, Li mentioned, because of “low threat of hot-spots, resistance to micro-cracks and distinctive mechanical load efficiency.”

Tongwei, which has 70 GW of annual cell capability – and plans to hit 130 GW to 150 GW by 2026 – reviews that it has 6 GW of Terra strains, whereas module capability has reached 14 GW, together with sequence of half-cuts.

IP claims

Whereas Tongwei’s adoption of shingling represents a serious technological advance in scale, the commercialization of shingling was years within the making. Silicon Valley-based Solaria Company, based in 2000, started promoting shingled PowerXT modules in 2016. Solaria claims to carry “greater than 250 issued and pending patents within the area,” which most of them, most likely, associated to shingling.

The California firm vigorously defends what it considers mental property (IP). In June 2022, it settled a patent infringement case filed in 2020 in opposition to Sino-Canadian producer Canadian Photo voltaic for allegedly infringing its shingling know-how.

Solaria desires to merge with installer Full Photo voltaic and float the ensuing Full Solaria enterprise as a vertically-integrated firm much like SunPower. Full Solaria can produce shingled PowerXT modules with an output of round 400 W beneath a “low capex [capital expenditure] mannequin,” with manufacturing “by producers in Thailand, Cambodia, Vietnam, and India.”

Steady IP

Tongwei mentioned it began module R&D in 2016 and hooked up significance to constructing an mental property system. “From the start of the shingled product challenge, Tongwei has already began the structure of the patent finish,” mentioned Li. “After seven years, Tongwei has fashioned an unbiased shingled know-how map.”

George Touloupas, senior director of know-how and high quality at high quality assurance supplier Clear Power Associates (CEA), factors to Tongwei’s statements that the corporate has “its personal method of connecting,” with out IP considerations. Touloupas added, “The chief know-how officer of the shingled module is from SunEdison and he brings his shingling expertise from that firm to Tongwei.”

Wanting beneath the hood, Touloupas discovered that the interconnection strategy utilized by Tongwei seems to have extra advantages. “Tongwei can be investigating a special interconnection know-how the place the shingled cells observe a jagged sample, which is extra secure in hot-spots and has much less loss because of shading.”

Matrix structure

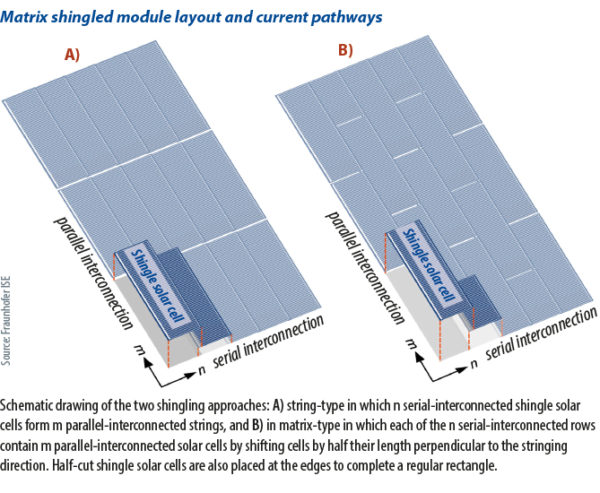

Researchers at Germany’s Fraunhofer ISE revealed check outcomes from such a shingled-module cell structure within the journal Progress in Photovoltaics in 2021. Within the paper, the researchers name the method a “matrix structure” during which the reduce cell items are positioned in an offset sample, “half a cell lengthy” – with half-cut shingle cells positioned on the sides to lead to a regular rectangular module format.

“By transferring the photo voltaic cells from row to row at half a cell size, a further parallel interconnection of all photo voltaic cells inside every row is achieved,” the researchers wrote. .

The Fraunhofer ISE workforce examined matrix shingled modules in numerous shading situations, together with shading diagonally throughout the module, and located that the matrix design resulted in a big improve in power yield. Electrical present can bypass shaded areas extra successfully because of the offset cell structure. The structure additionally reduces the chance of mechanisms inflicting hotspots – the results of partial shading.

As excellent, unshaded places for photo voltaic are more and more scarce, the Fraunhofer researchers concluded that the matrix structure can be notably precious. “Nice potential for solar energy era meets a big number of irregular shading situations, which makes shading tolerance an important facet,” the teachers wrote.

Challenges stay

Advances in shingling know-how, and its adoption on a bigger scale, level to know-how probably transferring into a brand new period of improvement. Competitors from different applied sciences will stay fierce, nevertheless.

“4 or 5 years in the past, shingled modules had [a] 10% effectivity benefit in comparison with odd – on the time – full-cell, four-busbar modules; that’s now not the case,” mentioned CEA’s Touloupas. “With the introduction of half-cut cells, multi-busbar, paving, or tiling; this 10% module space effectivity benefit has been exhausted.”

As Tongwei and different shingling advocates argue, there are a lot of benefits past effectivity. Using ECA over busbars, with lead, is one such benefit – including environmental credentials to the shingled technique, together with sturdiness, shading tolerance, and aesthetics. As with different high-efficiency applied sciences, the silver content material of ECA should proceed to lower so as to use it sustainably in massive volumes (see field).

Low-silver ECA

ECA has a comparatively excessive silver content material – as much as 70% to 80% was famous by lecturers in industrial merchandise in 2019. That will change, nevertheless, due to conductive particles coated with silver and optimized particle shapes. “We most likely began lowering silver consumption in our adhesives, perhaps 10 years in the past,” mentioned Wealthy Wells, chief know-how officer of Ohio-based, Japanese-owned Nagase Chemtex America. a producer with greater than 15 years of expertise in supplying photo voltaic corporations. . “Not too long ago, I might say within the final 5 years, there have been some very good achievements.” Wells mentioned the progress in lowering the ECA’s silver content material set for photo voltaic got here via two key developments. The primary is to exchange pure silver particles with silver-coated alternate options. Copper on the core of the particles, says Wells, “is without doubt one of the many choices on the market.” Nagase Chemtex labored with researchers from the Power Analysis Heart within the Netherlands to develop silver-coated particles for ECA. Ohio enterprise scientists are additionally attempting to optimize particle shapes. Longer, flatter particles present equal conductivity from a smaller quantity of conductive metallic. “The fashions for percolation, to construct a conductive community via the system, present that you could create the conductivity community at a low degree. [metal] loading when you’ve got a better facet ratio,” mentioned Wells. Mark Francis, the gross sales and advertising and marketing supervisor of Nagase Chemtex, has a protracted historical past within the semiconductor business. He mentioned, becoming a member of the corporate primarily to develop the photo voltaic enterprise, he was shocked to be taught that PV producers are utilizing lead solder for cell interconnection. “We’re seeing a push for silver discount within the cell grid and the interconnection,” Francis mentioned. I am considering, when are they going to show round and say we do not wish to do cell interconnection on lead anymore?”

Tongwei reviews that it’s working to optimize the bonding power of ECA and its conductivity – which it calls the non-silver and silver techniques, respectively. “We’re dedicated to bringing our environment friendly and eco-friendly Tongwei Terra sequence to extra properties,” the corporate mentioned.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.