Silver-alloyed CGIS solar cell with 18.7% efficiency – pv magazine International

Swiss scientists used a small quantity of silver to combine the absorber right into a thin-film CIGS photo voltaic cell. They are saying this course of helps to enhance effectivity, open circuit voltage, and fill issue, whereas compensating for the low bandgap of the CIGS layer.

Scientists from the Federal Laboratories for Supplies Science and Know-how (EMPA) in Switzerland have constructed a thin-film photo voltaic cell primarily based on copper, gallium, indium and selenium (CIGS) through the use of a small quantity of silver (Ag) to combine the CGIS absorber. They declare that the gadget can be utilized for tandem photo voltaic cell purposes.

“The quantity of Ag in CIGS could be very small; solely about 20nm or thinner Ag precursor layer for a complete CIGS thickness of about 3000 nm,” mentioned researcher Maximilian Krause. pv journal. “However the advantages when it comes to structural and digital properties to enhance photovoltaic conversion effectivity are excessive.”

The researchers say that using silver improves grain progress and crystal high quality, whereas decreasing dangerous defects and compensating for the low bandgap power of 1.0 eV within the CIGS absorber. The researchers used an preliminary layer methodology to deposit Ag on the absorber, in a three-stage means of co-evaporation of soda-lime glass.

“The absorbers are completed with a 35nm cadmium sulfide (CdS) buffer layer deposited in a chemical bathtub,” they defined. “Photo voltaic cells don’t cross warmth mild.”

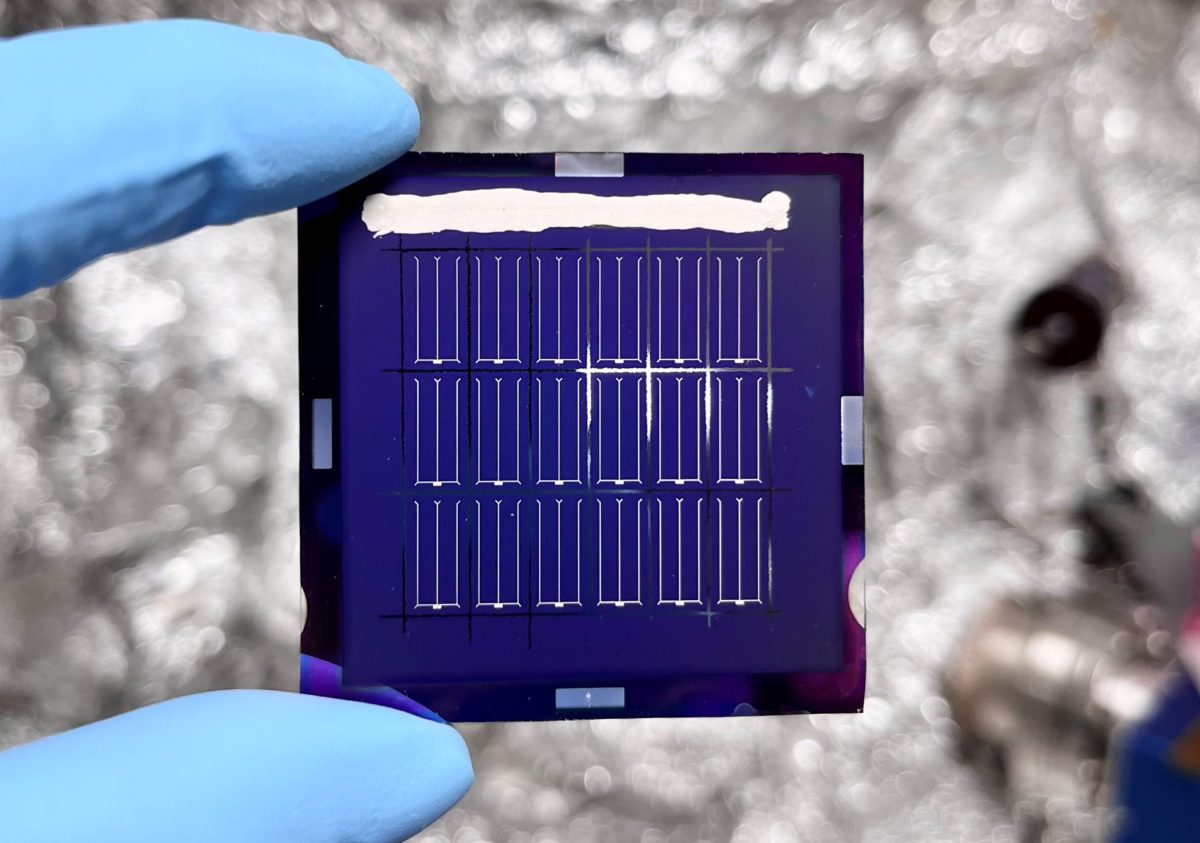

They constructed a cell with an space of 0.57 cm2 and an antireflective coating primarily based on magnesium fluoride (MgF2). Examined below commonplace lighting circumstances, one of the best efficiency gadget reveals an influence conversion effectivity of 18.7%, an open-circuit voltage of 602 mV, a short-circuit present of 42.1 mAcm .-2and a fill issue of 73.9%.

“Whereas Ag tends to increased open-circuit voltage and fill values, the short-circuit present doesn’t reveal related traits,” they mentioned.

Lecturers say that the rise in efficiency could also be as a result of the truth that Ag-alloying adjustments the interface of the cell as a result of it consists of a bi-layer construction with rubidium, indium, selenium (Rb-In -Se) layer and a Cu-depleted one. orders the emptiness compound OVC layer, which reduces the density of interface defects and acts as a passivation layer.

They describe the cell expertise, which they declare can be utilized for tandem photo voltaic cell purposes, in “Silver-alloyed low bandgap CuInSe2 photo voltaic cells for tandem purposes,” which was lately printed in RRL Photo voltaic.

“Till now, we’ve got not calculated the extra value, however the advantages will probably be vital if one considers the implication for industrial-level productions,” mentioned Krause, when requested about the price of cell manufacturing. “Our lab could be very desirous about additional technological growth and in direction of industrialization.”

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].