Scientists in Singapore have investigated all strategies of thermal evaporation for the manufacturing of perovskite photo voltaic cells and modules. Regardless of the constraints, new strategies can result in excessive manufacturing throughputs and extra environment friendly merchandise.

Scientists from Singapore’s Power Analysis Institute at Nanyang Technological College are investigating how thermal evaporation (TE) can be utilized to make mini perovskite photo voltaic modules. TE is a mature method that’s typically used on the microelectronic and optoelectronic industries to provide natural light-emitting diodes (OLEDs), metallic contacts, and coatings for numerous supplies.

“We analyzed the usage of a number of strategies based mostly on evaporation to create halide perovskite skinny movies,” mentioned researcher Annalisa Bruno. pv journal. “This ranges from comparatively easy single-source deposition and multi-source co-evaporation to extra advanced multistep evaporation and hybrids of thermal evaporation with gasoline response and resolution processing.”

He mentioned that this mixed strategy takes benefit of the benefits of each strategies. However he famous that it additionally has some limitations, resembling elevated complexity and the usage of solvents.

“We imagine that thermal evaporation is the perfect perovskite deposition methodology to make that speedy leap, as a result of it’s simply renewable, accommodates no hazardous solvents, and is already built-in into present strains within the manufacturing of opto- and microelectronics,” mentioned Bruno.

The researchers mentioned that one of many major problems with co-evaporation is the necessity for in depth optimization of the depotsition parameters for perovskites with advanced stoichiometries, particularly when greater than two or three precursors are evaporated on the identical time. Additionally they be aware how lengthy the deposition time could be an impediment for business manufacturing, since most research on these strategies are inclined to ignore this challenge.

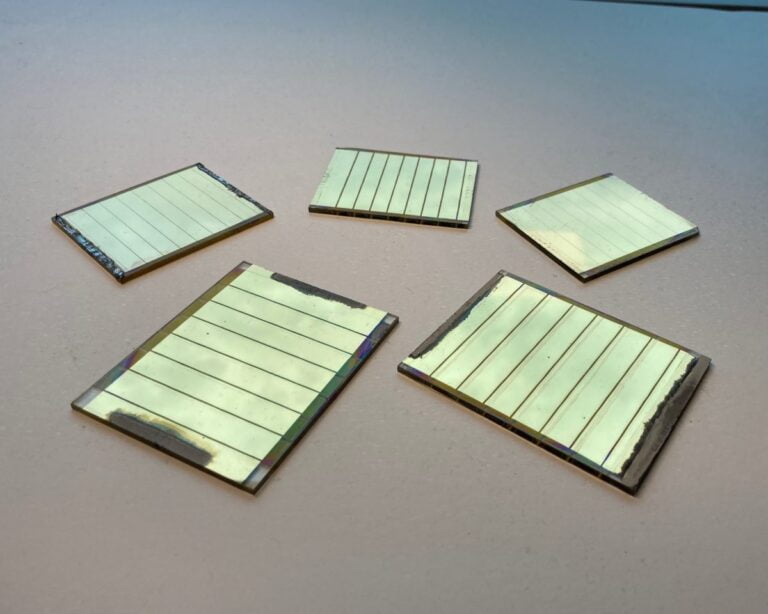

Their evaluate presents a sequence of strategies for the manufacturing of perovskite photo voltaic cells and mini modules. These strategies embrace one-step thermal evaporation, multi-step thermal evaporation, and multi-step hybrid deposition.

“I’mt could also be fascinating to provide no solely evaporated perovskite movie but additionally absolutely evaporated modules utilizing identical fabrication strains,” mentioned the group.

Benefits are reported to incorporate a excessive course of degree management, exactly controllable movie thickness, straightforward successive addition of many layer, and low substrate temperature processability. The researchers say that the strategies might also allow higher purification of precursors throughout movie formation, wonderful spatial uniformity inside gadget batches, good reproducibility over a number of fabrication rounds, and excessive yield of manufacturing.

“Qe complete course of could be automated and managed, making it intrinsically enticing for large-scale and high-throughput manufacturing,” they mentioned.

They describe the manufacturing strategies of “Thermal evaporation and hybrid deposition of perovskite photo voltaic cells and mini-modules,” which was lately printed in Joule.

“We imagine that the way forward for analysis on this subject ought to take a look at new optimum gadget interlayers to enhance the standard of the lively materials and the transparency, transmission of defects by way of strategies based mostly on vacuum, and enhance operational stability to maximise and understand the total potential of thermally evaporated perovskite photo voltaic units,” mentioned Bruno.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.