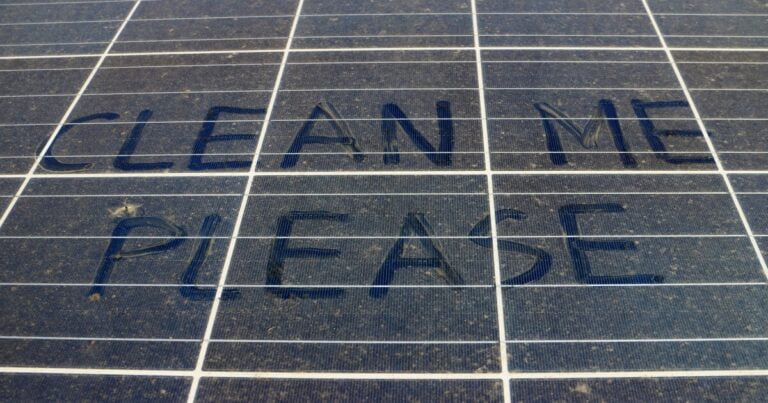

Photo voltaic panels do not work properly after they’re clogged with filth, however cleansing them can typically be a time-consuming course of. German engineers have now developed an ultra-thin coating that may make photo voltaic panels and different surfaces self-cleaning.

Photo voltaic is the most important supply of renewable power, and it’s rising quickly. However as you may think about, it’s not attainable to ship somebody with a squeegee to wash the hundreds of thousands of photo voltaic panels in each park. Cleansing themselves can be preferrred – and now researchers on the Fraunhofer Institute in Germany have taken steps in the direction of that idea.

The workforce developed a coating that modifications its response to water based mostly on the time of day, permitting it to shed any accumulation of mud and filth shortly. The primary ingredient is titanium oxide, which in its regular state repels water, forming droplets that disappear shortly. When titanium oxide is uncovered to UV mild, nevertheless, it modifications state to turn out to be extremely water-attractive, preserving the floor moist with a skinny layer of water.

Actually, it makes for a self-cleaning coating. Mud or filth that accumulates in the course of the day can’t keep on with the floor as a result of a skinny layer of water prevents it, then at evening the water grows into droplets that roll simply, carrying the filth with it. As a bonus, when titanium oxide is activated by UV mild it destroys natural molecules, successfully sterilizing the floor.

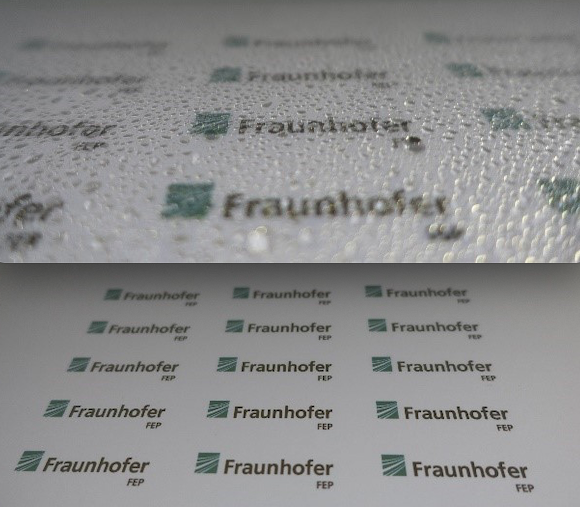

Fraunhofer FEP

The final thought has been applied in self-cleaning glass earlier than, however it normally entails both a mechanism to repel water or appeal to water, not each. Even higher, the Fraunhofer workforce’s new coating is designed to be mass produced roll-to-roll, and might be utilized to current photo voltaic cells, home windows and different surfaces.

Within the assessments, the workforce used a pilot plant to provide rolls of skinny glass 30 cm (11.8 in) vast, 20 m (65.6 ft) lengthy and solely 100 micrometers thick, with the titanium oxide coating as much as 150 nanometers thick.

In fact there are obstacles that also must be overcome. The workforce says the skinny glass continues to be very fragile, and weak to warmth. Future work will concentrate on its enchancment, investigating the potential for utilizing polymer movies.

The analysis shall be offered on the BAU commerce honest in Munich in April.

Supply: Fraunhofer Institute