From pv journal 03/23

IBC photo voltaic cells had been conceived within the Nineteen Seventies and the concept behind them is straightforward: Transfer all of the contacts, metallization, and different inside elements of the cell to the again aspect, leaving the entrance, energetic layer intact. closed and open to numerous daylight.

That strategy ensures that the IBC, and different back-contact kind gadgets, can push nearer to the sensible restrict for single-junction silicon cell conversion effectivity than different cell architectures. That purpose has saved them targeted on researchers, with lots of the highest in-lab efficiencies coming from back-contact buildings.

Processing back-contact cells at scale, nonetheless, has confirmed tough and costly. The ensuing lack of adoption signifies that comparisons of mainstream approaches are tough. “As the size of the again contact is small and is principally utilized in distributed technology initiatives that preserve a greater look, it has a better premium,” stated Corrine Lin, principal analyst. of market intelligence firm rebranded InfoLink. “Based mostly on present producers’ product pricing, there’s sometimes a premium of $0.01/W, or greater, in comparison with PERC [passivated-emitter, rear contact solar]. Nevertheless, there isn’t a clear premium index as a result of small buying and selling volumes and totally different goal markets.

Most main producers have taken a less complicated route to enhance effectivity, however with more cost effective strategies which are approaching exhaustion – and researchers at Germany’s Institute for Photo voltaic Vitality Analysis Hamelin final yr calculated again -contact gadgets can hit 29.1% effectivity – the renewed makes an attempt to commercialize again- Contact cells can be found.

IBC benefit

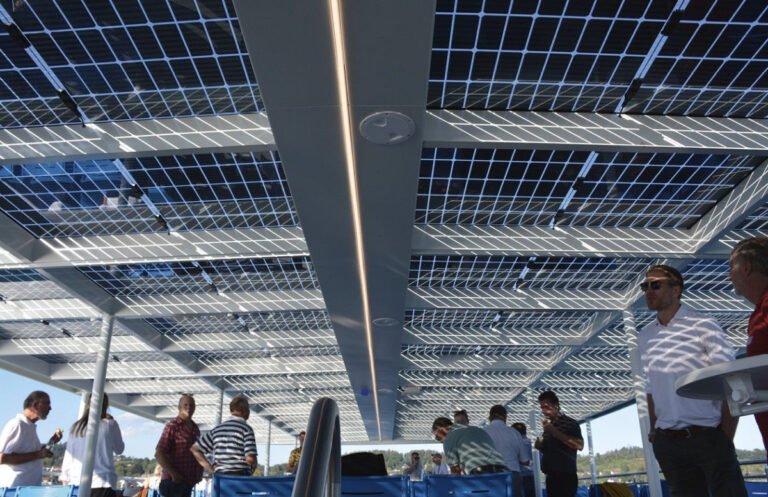

The US firm SunPower Company has been manufacturing IBC cells for over 20 years. Its merchandise are significantly profitable within the residential market, the place aesthetic look and superior effectivity and reliability are extremely valued, leading to a premium value. In 2020, SunPower spun off its manufacturing enterprise to kind a brand new firm, Maxeon Photo voltaic Applied sciences, which continues to fabricate IBC merchandise beneath the SunPower and Maxeon manufacturers.

Doug Rose, vp for expertise technique at Maxeon, explains that the again contact construction permits full optimization of the entrance floor, maximizing cell brightness and minimizing recombination, as a substitute of getting to additionally optimize for steel protection and lateral conduction in steel fingers. . On the again aspect, IBC permits for thicker steel, leading to decrease sequence resistance.

Rose added that, together with effectivity, superior reliability can also be a spotlight for Maxeon, and having a premium product permits it to make design and supplies decisions that lead to superior reliability. than regular – it provides a product assure of as much as 40 years in some. markets.

A key benefit of Maxeon’s IBC merchandise is that they’ve a singular, non-destructive reverse-bias conduct. This prevents hot-spots – which may trigger harm to cells and modules – even in partial shade with failed module diodes. “We imagine it offers added worth and differentiation and we’re placing a whole lot of effort into extending the benefit of this space to our future generations.” Rose additional explains that the flexibility to do that is one other inherent benefit of again contact expertise, though not all again contact architectures.

State of play

There are excessive hopes for back-contact photo voltaic. Radovan Kopecek, co-founder and director of the German institute of the Worldwide Photo voltaic Vitality Analysis Heart (ISC) Konstanz, stated pv journal in November, IBC modules might meet up with TOPCon (tunnel-oxide, passivated contact) merchandise in 2028 and make up half of the market in 2030. Some market observers are much less bullish however agree that the again contact applied sciences will probably see development within the subsequent 5 years.

“Steady enhancements in manufacturing processes and effectivity have led to a gradual discount in prices for many back-contact applied sciences,” stated Karl Melkonyan, senior analysis analyst at enterprise intelligence agency S&P International Commodity Insights. “A big price discount, nonetheless, will take a whole lot of time to totally develop. It might be a big discount in silver consumption; or a complete substitute of copper or aluminum; or further advances in soldering and cell interconnection processes, and different enhancements in effectivity, yield, and availability.

S&P International predicts that back-contact photo voltaic may obtain a 15% market share within the subsequent 5 years. InfoLink expects development of round 5% within the subsequent two to a few years however little after that. “For the long run, its market share is unlikely to achieve the size of PERC or TOPCon because of the advanced course of and better manufacturing prices,” Lin instructed InfoLink. “Even when there’s nonetheless demand for back-contact – as a result of excessive effectivity and higher look – its market share is unlikely to achieve 10%.”

Maxeon pursues such enhancements within the manufacturing course of. “Maxeon has a totally proprietary course of with a number of patents defending the tactic,” stated David Smith, a scientist at Maxeon’s California R&D hub. “The processes we now have in pilot manufacturing now use extra mainstream gear, so we are able to trip the coat tails of the TOPCon business. We use these huge, high-powered gadgets as a lot as potential and our new technology makes use of a better proportion of these than earlier than.

Save and scale

Maxeon, nonetheless, remains to be targeted on clients who can pay a premium for efficiency and aesthetics, and says it is going to proceed to concentrate on its product vary, whilst extra of the IBC applied sciences debut. to look.

ISC Konstanz believes that the associated fee reductions required to assist IBC’s robust expectations will be realized. The analysis heart developed “Zebra” IBC cells which are available on the market by means of manufacturing companions in Europe and Asia, and proceed to decrease manufacturing prices and enhance effectivity.

“Our goal is that, from the associated fee construction perspective, as a lot as potential with commonplace expertise,” stated Joris Libal, ISC’s mission supervisor for expertise switch. “We need to begin with low cost processes, straight from the toolbox, and attain excessive effectivity.”

Valentin Mihailetchi, chief of the n-type group [negatively-doped] cell R&D at ISC Konstanz, went on to clarify that Zebra cells are made utilizing typical processes together with tube diffusion, display screen printed metallization, plasma enchaced chemical vapor deposition, and laser ablation, including, “It is about to make use of the processes which are already established, in a barely totally different method.” That strategy can convey extra advantages as a result of the back-contact structure will be mixed with passivating contacts and different cell designs, providing one other path to mass manufacturing.

Consumption of silver

Moreover processing prices, IBC cells require silver contacts for a similar polarities. “In comparison with p-type [positively-doped] PERC, there could also be 5% extra price for the wafer and a slight distinction within the depreciation of the gear as a result of there’s much less gear in comparison with PERC or TOPCon,” stated Libal. “The principle distinction is the price of the steel.”

With little must make its back-side fingers as skinny as potential within the back-contact cells, nonetheless, ISC Konstanz makes use of copper paste as a substitute of silver within the screen-printing course of. Standard producers, in distinction, must make additional enhancements in copper plating processes to scale back the silver content material.

Whereas ISC Konstanz’s IBC cells nonetheless require silver for contacts – copper can’t be in direct contact with silicon – Libal says that silver consumption will be lowered to lower than 5 mg/W to supply capability. cell. That is a fraction of the quantity utilized in PERC and TOPCon cells and helps ease business considerations about silver provide.

The analysis institute is engaged on the copper display screen printing course of and says it has achieved good ends in accelerated testing up to now. “The Zebra IBC cell with copper metallization might be a breakthrough that can lastly convey the price of the IBC beneath PERC, with effectivity nonetheless above,” stated Libal. “If these primary price and efficiency parameters are met, that is when it is going to fly.”

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: editors@pv-magazine.com.