Australian scientists have developed a brand new technique to produce hydrogen straight from seawater. They describe the know-how as a essential step in a very viable inexperienced hydrogen trade.

From pv journal Australia

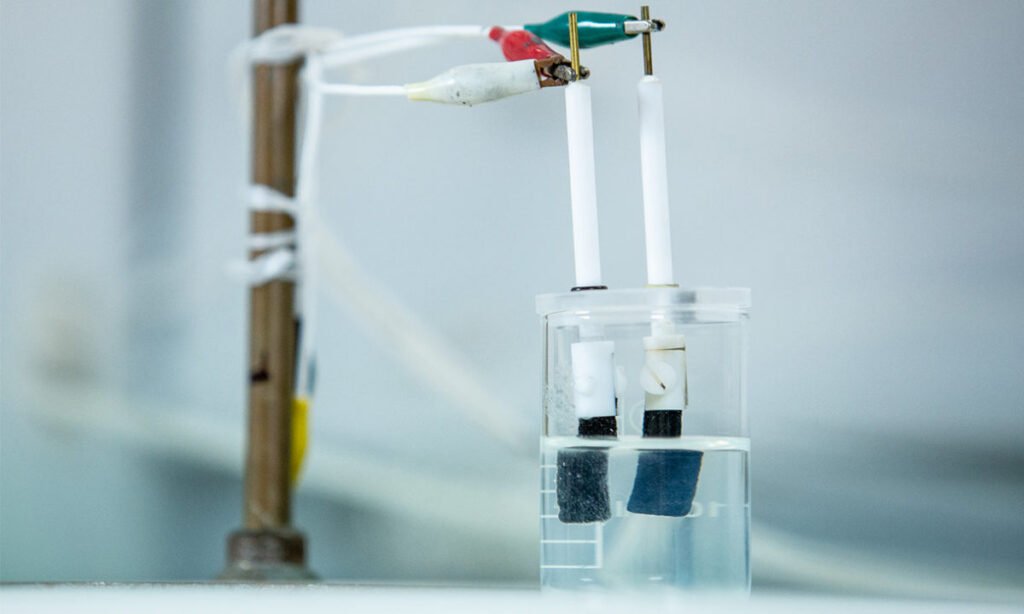

Researchers from RMIT College in Melbourne, Australia, have developed a brand new technique to cut up seawater into hydrogen and oxygen, eliminating the necessity for desalination and its prices, vitality consumption, and poisonous byproducts. . They comprise a catalyst made up of nitrogen-doped porous sheets made to work particularly in seawater.

The brand new technique, developed by a workforce within the multidisciplinary Supplies for Clear Vitality and Surroundings (MC2E) analysis group at RMIT, makes use of a catalyst composed of nitrogen-doped porous nickel molybdenum phosphide sheets. The tactic, detailed in a lab-scale research lately printed in smalldepends on the presence of enormous pores within the sheets to extend electrical conductivity whereas the presence of metal-nitrogen bonds and floor polyanions will increase stability and improves anti-corrosive properties towards chlorine chemistry.

The researchers stated the catalyst sheets confirmed “outstanding efficiency,” catalyzing your complete water cut up at 1.52 and 1.55 V to attain 10 mA cm−2 in 1 m KOH and water. of the ocean, every.

“Thus, structural and compositional management could make catalysts efficient in realizing low cost hydrogen straight from seawater,” the workforce concluded.

Lead researcher Nasir Mahmood stated the brand new technique overcomes a few of the obstacles related to seawater’s salty nature.

“The most important impediment to using sea water is chlorine, which generally is a by-product. If we meet the world’s hydrogen wants with out fixing this difficulty first, we are able to produce 240 million tons per 12 months of chlorine per 12 months – which is three to 4 occasions what the world wants of chlorine,” stated Mahmood. “There is no such thing as a level in changing fossil fuel-produced hydrogen with hydrogen manufacturing that might hurt our surroundings another way. Our course of not solely removes carbon dioxide, but in addition doesn’t produce chlorine.

Whereas different experimental catalysts are being developed for seawater splitting, PhD candidate Suraj Loomba stated the RMIT analysis workforce was targeted on creating extremely environment friendly, steady catalysts that could possibly be successfully at price.

“Our method is concentrated on altering the interior chemistry of catalysts by means of a easy technique, making them straightforward to supply on a big scale in order that they are often simply synthesized on industrial scales,” he stated.

Mahmood says the know-how holds the promise of decreasing the price of electrolyzers – sufficient to fulfill the Australian authorities’s objective for inexperienced hydrogen manufacturing of $2 per kilogram, making it aggressive with fossil-sourced hydrogen. gas.

“Our technique of manufacturing hydrogen straight from seawater is straightforward, scalable and less expensive than any inexperienced hydrogen method presently available on the market,” he stated. “With additional improvement, we hope this can advance the constructing of a thriving inexperienced hydrogen trade in Australia.”

A provisional patent utility has been filed for the brand new technique and the researchers say they’re working with trade companions to develop the know-how. The subsequent stage is the event of a prototype electrolyzer that mixes a collection of catalysts to supply massive portions of hydrogen.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.