Australian startup reveals 20-layer battery cell based on semi-solid li-sulfur technology – pv magazine International

Brisbane-based Li-S Power has developed a 20-layer battery cell that makes use of semi-solid state lithium sulfur battery expertise. The corporate claims that the brand new cell reveals virtually twice the gravimetric power density and a comparable volumetric power density to lithium-ion cells.

In comparison with the ever-present lithium-ion expertise, lithium-sulfur batteries have the potential to supply cheaper, lighter weight power storage, in addition to value and security benefits. However the widespread use of those batteries faces obstacles primarily from the constraints of the life span of lithium-sulfur cells.

In a bid to deliver this expertise nearer to commercialization, Australian listed firm Li-S Power has introduced the event of its first 20-layer battery cells utilizing third-generation (GEN3) semi-solid state lithium sulfur battery expertise.

Li-S Power is working with Victoria’s Deakin College and PPK Group, amongst others, to develop new battery cells, which remove heavy metals akin to nickel, cobalt and manganese utilized in lithium-ion battery.

The Li-S Power cell is claimed to supply a volumetric power density of 540 Wh/l, a gravimetric power density of greater than 400 Wh/kg and improved security with the usage of a low-flammability electrolyte.

The GEN3 battery cell has main benefits over the second technology iteration, together with a forty five% improve in volumetric power density due to the usage of low porosity cathode materials.

In comparison with present Li-ion cells, this efficiency is sort of twice the gravimetric power density and an analogous volumetric power density. This implies Li-S Power’s battery cells are actually the identical measurement as present Li-ion batteries however half the burden, the corporate mentioned.

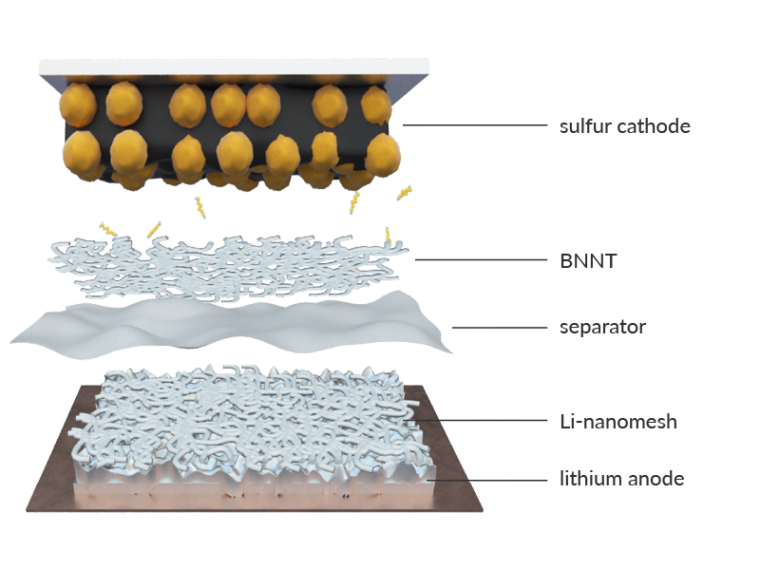

The 20-layer cells use Li-S Power’s patented Li-nanomesh expertise and incorporate boron nitride nanotubes (BNNTs) into the cell development to cut back dendrite progress and enhance security and cycle life. Take a look at cells demonstrated steady efficiency over 1,000 charge-and-discharge cycles whereas sustaining a particular capability roughly 3 times that of a typical lithium-ion cell.

The brand new cells are being manufactured at Li-S Power’s Part 2 facility in Geelong, Victoria, the place cell manufacturing trials are anticipated later this yr, as soon as the corporate’s Part 3 facility is full. Part 3 is a 2 MWh manufacturing line, which can allow extra automated manufacturing and can embody presumably the biggest dry room in Australia.

“Within the coming months we look ahead to starting the manufacturing of economic samples for our companions,” mentioned CEO of Li-S Power, Lee Finniear.

At this level, the Li-S Power growth group is working to enhance the cell cycle testing and characterization outcomes to supply an business normal datasheet of the brand new 20-layer cells.

Li-S Power has recognized electrical aviation and drones as a key sector the place it has a aggressive benefit as a result of mild weight of its batteries. In 2022, the battery startup signed an settlement with US-based e-aviation firm magniX, which can take a look at the potential of the corporate’s expertise for e-aviation functions.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].