Scientists in Belgium have designed a solar-powered electrolyzer that makes use of standard-sized, large-area shingled silicon PV for water splitting. The system is reported to be able to attaining solar-to-hydrogen effectivity of 10% at electrolyzer present densities of roughly 60 mA cm−2.

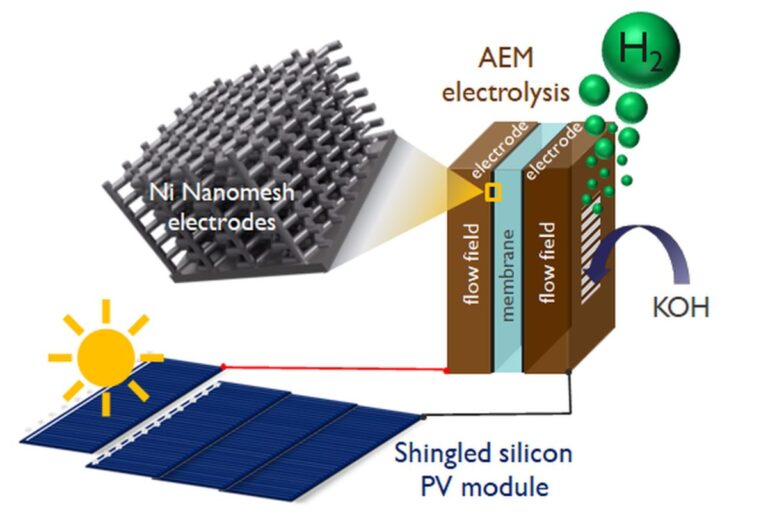

Researchers at Imec in Belgium have developed an anion change membrane (AEM) electrolysis of water for hydrogen era. They are saying their methodology might be mixed with photo voltaic era in a photovoltaic-electrolyzer (PV-EC) configuration.

“The innovation of our strategy consists of utilizing standard-sized large-area shingled silicon PV to offer over 1.23V for water splitting mixed with low-cost anion-exchange water electrolysis, which mixes the upper densities of the present operation of the polymer electrolyte membrane (PEM) with low-cost supplies from alkaline electrolysis,” mentioned researcher Nina Plankensteiner pv journal.

The scientists offered their findings in “Photovoltaic-Electrolyzer System Operated at > 50 mA cm-2 by Combining Giant-Space Shingled Silicon Photovoltaic Modules with Excessive Floor Space Nickel Electrodes for Low-Value Inexperienced H2 Era,” which was just lately revealed in RRL Photo voltaic. They defined that PV-ECs provide the very best degree of expertise readiness and highest solar-to-hydrogen efficiencies of all electrolyzer applied sciences.

“In PV-EC methods the photovoltaic expertise of selection, which commercially delivers low-cost electrical energy with a secure effectivity of 20-25% at 30-40mA/cm2, are in-series linked silicon photo voltaic cells, which offer > 1.23V for water splitting,” says researcher Joachim John. “Within the subsequent decade, silicon-tandem configurations with perovskite top-cells could play a further position in conversion efficiencies of round 30%.”

They describe the proposed system as having a “commercially related configuration.” They mentioned that the AEM electrolyzer has nanomesh electrodes with a big floor space of 26 m2/cm3 fabricated from nickel-rich soil, as beforehand reported by researchers.

“The in-series shingling of silicon photo voltaic cells is a really enticing methodology for photo voltaic water splitting functions, as a result of a sufficiently excessive voltage per commonplace cell space might be achieved,” they are saying, in reference to shingled panels.

The modules haven’t any busbar buildings, with solely a small a part of the cells not uncovered to the solar. The cells are certain to type a shingled high-density string and the ensuing strips are linked by a conductive adhesive. Decreasing the variety of busbars reduces shadow losses.

The lab-scale, single-cell electrolyzer developed by lecturers has two 4-micrometer skinny high-surface space nickel nanomesh electrodes. It additionally options six silicon heterojunction cells with shingles of 38.5 cm2 reduce from 15.6 cm2 x 15.6 cm2 commonplace cells.

“The cells are linked in sequence and supply a variable open-circuit voltage vary from 0.7V to 4.3V, relying on the variety of cells linked,” the scientists defined, noting that the cells achieves a mean effectivity of round 20% and a fill issue of roughly 80%. “The present-voltage traits from the electrolyzer present that 1.8 V to 2.2 V is required to match an electrolyzer present density between 20 and 100mA/cm2. This minimal voltage requirement might be achieved by connecting three or 4 silicon cells in-series.

Examined beneath commonplace lighting circumstances, the PV-EC system was reported to supply hydrogen in about 20 hours and achieved a solar-to-hydrogen effectivity of 10% on the electrolyzer present density. which is roughly 60 mA cm-2which the workforce described as the very best density reported for PV-EC methods within the literature.

Photo voltaic-to-hydrogen effectivity is decided by in-situ monitoring of an important system parameters, equivalent to working present, voltage, and hydrogen fuel move. The researchers say that the correct willpower of this determine of advantage is vital when evaluating PV-EC methods to one another. They notice that larger stability measurements ought to be examined at excessive sufficient present densities to emphasize the system.

The researchers additionally carried out a sequence of efficiency dynamic load exams with gradual and sudden adjustments in energy enter throughout half a 12 months of photo voltaic radiation. They declare that exams present that cell voltage adjustments are small and have little affect on PV-EC operation and hydrogen manufacturing.

“The subsequent steps in the direction of the commercialization of the offered PV-EC system are long-term out of doors stability exams along with larger load measurement protocols,” they concluded.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.