Renewables-powered steam heat pump for industrial applications – pv magazine International

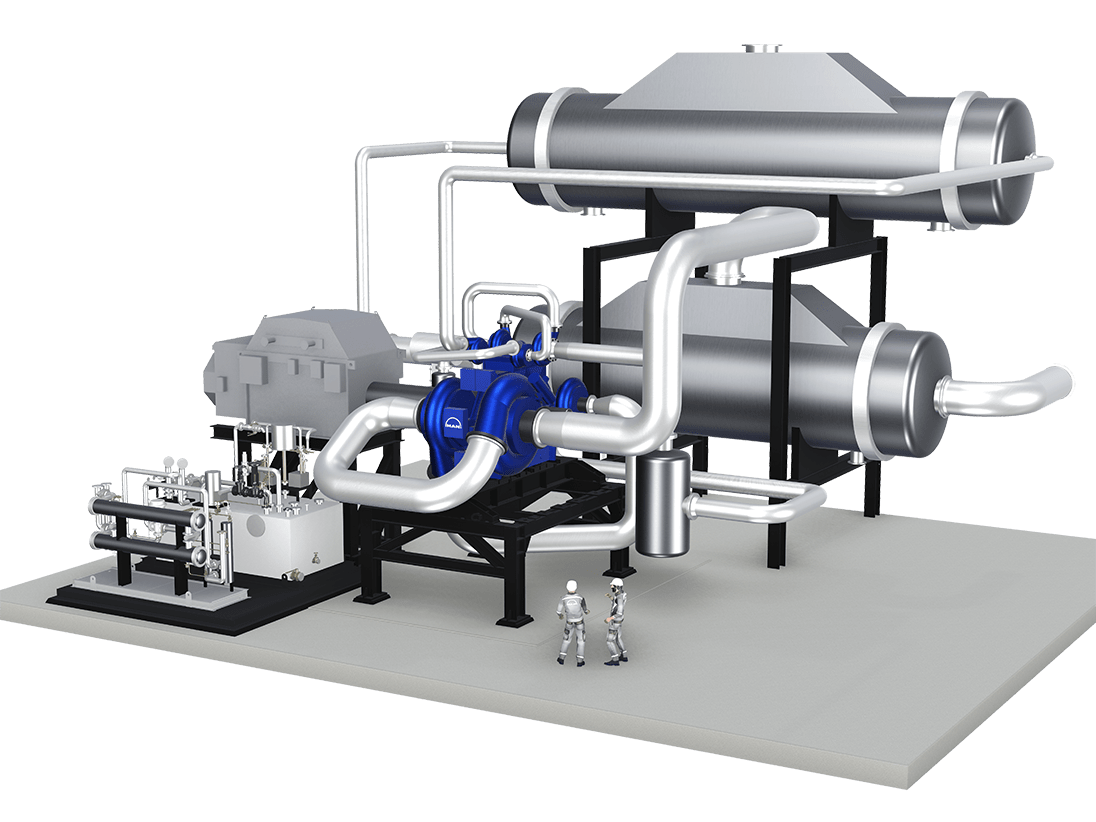

MAN Vitality Options has constructed an industrial-scale warmth pump that produces steam with out utilizing gasoline. It’s going to produce steam to dry milk elements on a dairy farm in New Zealand.

MAN Vitality Options, a producer of engines and turbomachinery options primarily based in Germany, introduced that it’ll check the design and implementation of a steam-generating industrial-scale warmth pump.

The know-how can be powered by electrical energy from renewable sources resembling photo voltaic, hydro, geothermal and wind, in accordance with MAN’s assertion. It’s going to generate steam to dry milk elements for Frontera, a dairy cooperative primarily based in New Zealand.

“After integration with Fonterra’s manufacturing infrastructure, the warmth pump will produce greater than 30 metric tons of course of steam per hour, equal to a thermal output of 25 MW,” MAN mentioned in a press release with out elaborating. extra technical particulars. Dairy farm CO2 manufacturing could be diminished by 60,000 metric tons per yr.

Step one of the mission will conduct an engineering research to enhance the mixing of the warmth pump resolution into the present milk powder manufacturing of the cooperative. This research is anticipated to be accomplished by the tip of April 2023, in accordance with MAN. The findings will then be used to design a warmth pump system at one in all Fonterra’s manufacturing websites.

“At Fonterra the world’s third largest dairy ingredient producer, we’re very excited to assist their decarbonization journey with our experience and cutting-edge know-how options,” mentioned Uwe Lauber, CEO of MAN Vitality Options.

The milk producer introduced the set up of a biomass boiler to switch a coal boiler at one in all its websites final yr, which is anticipated to be operational by the tip of November 2023. Its funding in warmth pumps utilizing renewable vitality sources as a part of its dedication to transition from coal in its manufacturing operations.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].